Manufacturing

CMMS Software for Manufacturing

Top manufacturing companies use UpKeep to meet production and safety goals all while keeping downtime costs to a minimum. With CMMS for manufacturing, you can utilize one easy-to-navigate solution to optimize your business.

No credit card required.

Check Out These Results From Top Businesses Who Use UpKeep’s CMMS for Manufacturing

90%

Reduction in technician time spent filing work orders and locating asset information

315%

Return on Investment

$638K

Savings from avoided production downtime

Trending Resources in the Manufacturing Industry

Essential Tips for Moving From Reactive To Preventive Maintenance

For most companies, the idea of moving from reactive to preventive maintenance is out of the question, even before the discussion starts. But there's good news for those who choose to take on the challenge. With UpKeep’s CMMS software for manufacturing, it's not an impossible feat.

Understanding Generational Shifts in the Maintenance and Manufacturing Industries

In this episode of Masterminds in Maintenance, Ryan and Sean Fitzgerald of ThomasNet discuss how to lead different generations in the workplace effectively and how manufacturers in the modern age can create an appealing culture for the generation to come.

Learn Ways To Improve Production Efficiency at Your Facility With Manufacturing CMMS Software

No matter how large or small your manufacturing plant, the efficiency and productivity of your capital investment are the keys to maintaining your competitive edge. As you implement these methods and track your progress through CMMS for manufacturing, your facility should start seeing increased production efficiency, including increased equipment uptime and decreased defects.

Discover the Benefits of Utilizing Manufacturing CMMS Software for the Manufacturing Industry

The right CMMS software for manufacturing can be a revolutionary tool to help manufacturing companies manage and optimize their production facilities.

With UpKeep’s CMMS software for manufacturing, you can enhance your operational efficiency, extend equipment lifespans, and boost productivity and profitability:

Ensure uninterrupted operations by facilitating proactive maintenance rather than reactive fixes.

Allow manufacturers to schedule and track maintenance tasks efficiently, reducing unplanned downtime and the associated production losses.

Anticipate equipment failures through predictive analysis, helping to replace or repair machinery before it breaks down, further reducing downtime and costly repairs.

Streamline inventory management, ensuring all spare parts and supplies are readily available when needed.

MANUFACTURING

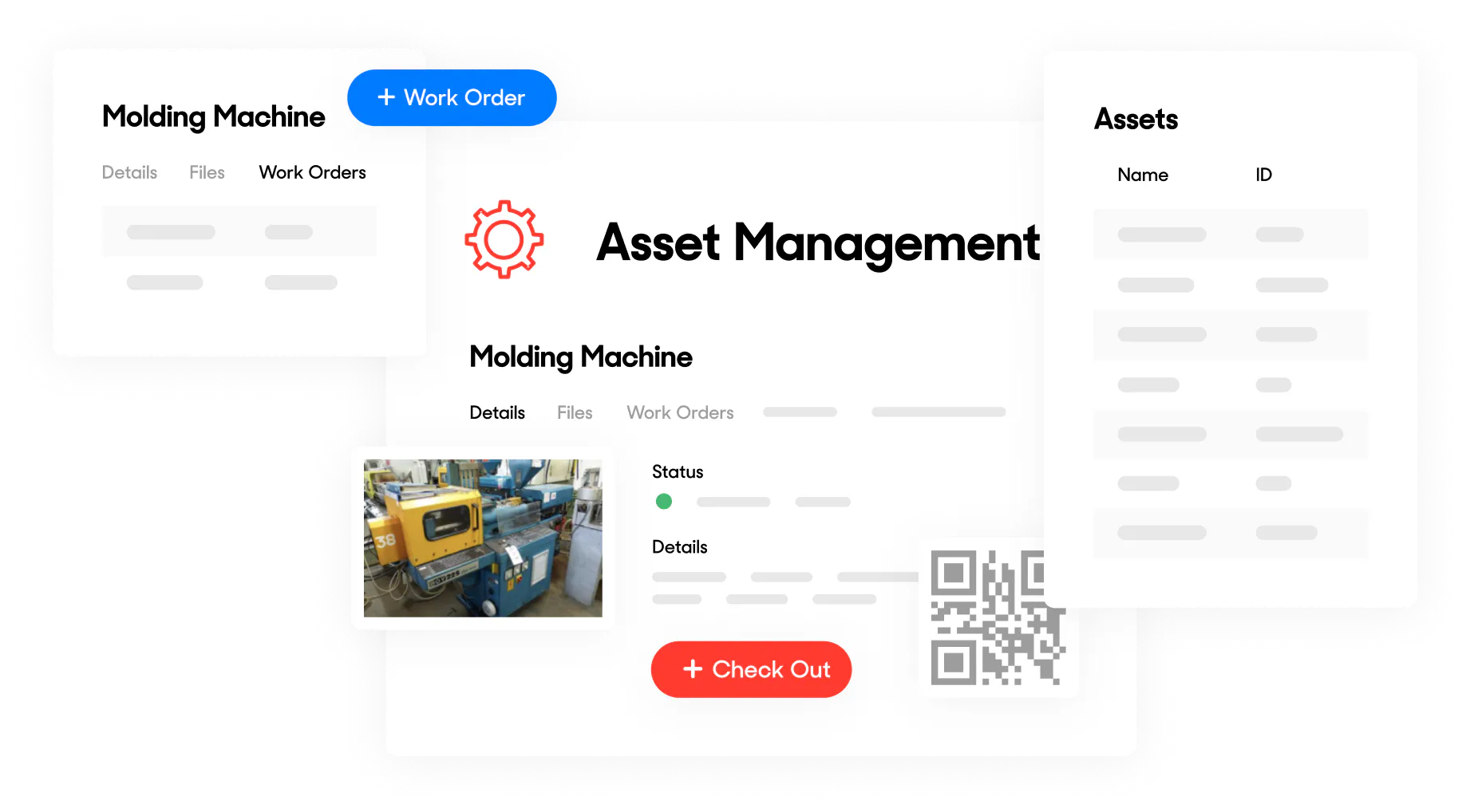

One Centralized Command Center for Maintenance and Reliability Teams

Maintenance for manufacturing shouldn’t mean guesswork and paperwork. UpKeep’s CMMS for manufacturing makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

CMMS, Maintenance Management, and Work Order Software

UpKeep is consistently rated the best inventory management CMMS software for manufacturing in value for money, ease of use, functionality, and customer support. There’s a reason UpKeep has more 5-star reviews than any other manufacturing CMMS software.

Reduce your equipment and asset downtime by up to 26%.

Extend your asset and equipment lifetime by up to 11%.

Achieve up to 652% ROI by integrating UpKeep’s manufacturing CMMS into your workflow.

Improve overall facility conditions with the integration of UpKeep’s manufacturing CMMS software.

UPKEEP EXPERTS HERE TO HELP YOU

Incomparable Training, Implementation, and Support To Ensure Your Success

From expedient account setup, secure data migration, and professional online team training to 24/7 customer support, we’ve got you covered every step of the way as you implement our manufacturing CMMS software.

The UpKeep Customer Success Team works like an extension of your team, helping customers hit their maintenance goals by providing useful resources, reliable support, and a personalized plan to help you grow.

Mobile Features for Manufacturing

Capture and Share Work Orders From Anywhere

Technicians can easily track insights on asset runtime and use on their smartphones and incorporate meter readings into regular preventive maintenance to maximize asset lifespan and ROI.

Paired with UpKeep Edge, IoT sensor meter readings are automatically recorded in UpKeep’s CMMS. If a reading falls before a threshold, UpKeep can automatically fire out a work order and notify the right technician to take immediate action.

FAQs About CMMS Software for Manufacturing

Yes!

Upkeep’s CMMS software for manufacturing incorporates predictive maintenance capabilities that use data analytics and algorithms to predict equipment failures.

The accuracy of these predictions will vary, but it tends to improve over time. The software becomes “smarter” as it encounters historical data and real-time sensor information.

UpKeep’s manufacturing CMMS software has all the features you need, including:

- Work order management – Enlist automation to easily generate, assign, and distribute your work orders, complete with all the information needed for repairs.

- Parts and inventory – Hassle-free tracking of your maintenance, repair, and operations inventory across all locations.

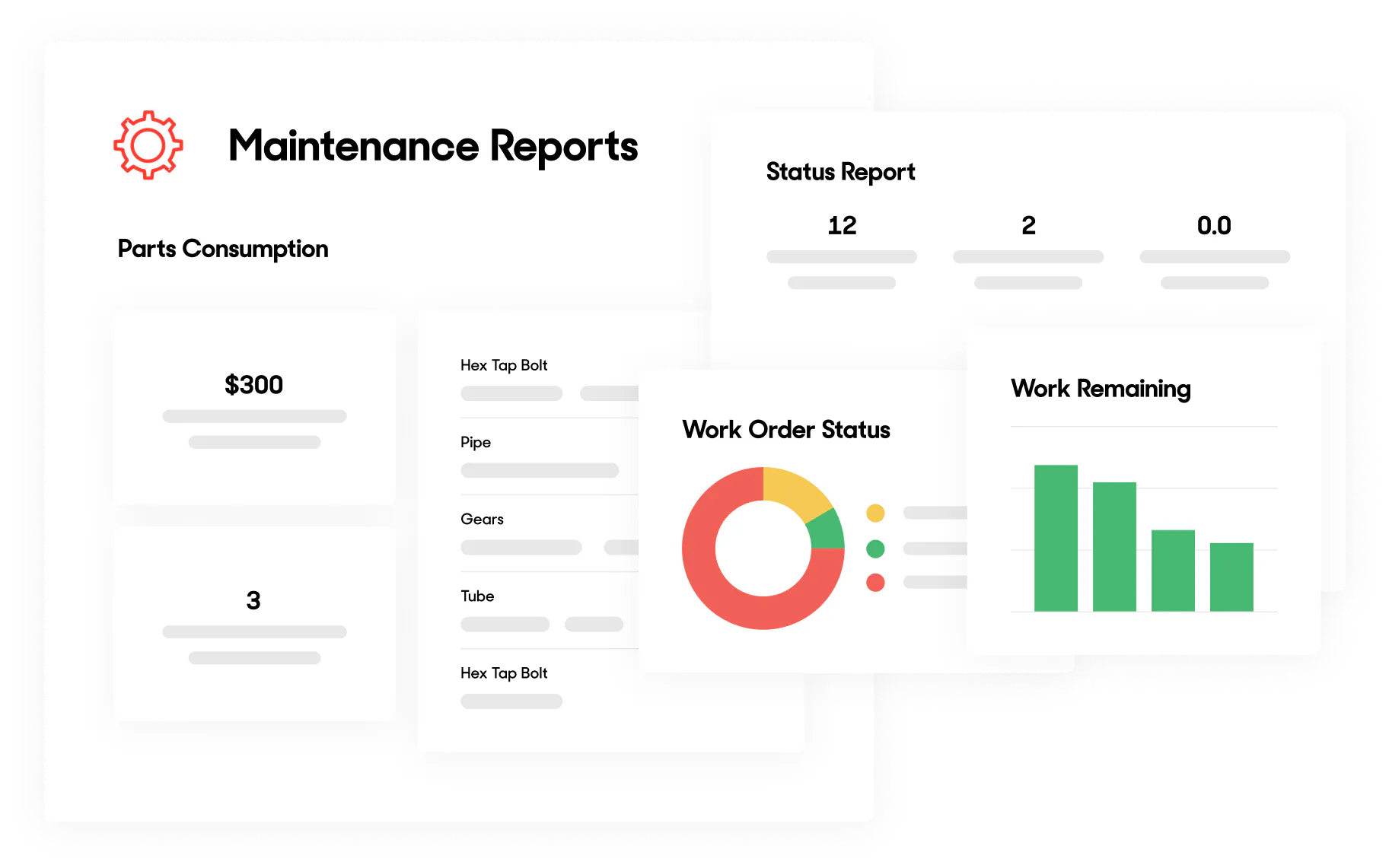

- Analytics and reporting – Easily create and share reports that contain the information you need to make wise, data-driven decisions around your operations and maintenance staff.

- Asset management – Store all of your company’s assets and equipment information in one centralized, easily accessible location.

- Preventive maintenance – Automate the scheduling of all aspects of routine maintenance to avoid the need for those more costly, unplanned repairs.

- Maintenance requests – Automatically track and manage your incoming service requests and communicate work request status.

- Mobile access for field teams – Put the power of your manufacturing CMMS in the palm of your hand.

UpKeep’s maintenance software for manufacturing companies helps reduce unplanned downtime by allowing maintenance teams to schedule preventive maintenance, monitor equipment health in real time, and predict potential failures.

This proactive approach ensures that equipment is well-maintained, reducing the likelihood of unexpected breakdowns.

The cost of implementing UpKeep’s manufacturing CMMS will vary depending on factors such as the:

- Size of your manufacturing facility

- Complexity of your equipment

- Software provider and package you choose

- Specific features you require

Costs may also include software licensing fees, implementation and training costs, ongoing support, and maintenance expenses.

Absolutely!

At UpKeep, we walk you through each step of our CMMS software for manufacturing, from expedient account setup to secure data migration to professional online team training.

We’re available 24/7 to provide customer support, with the UpKeep Customer Success Team working like an extension of your team to help you hit your maintenance goals.

You’ll get:

- Useful resources

- Reliable support

- A personalized plan to help your business grow

Explore Case Studies

Explore more case studies4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability