IIOT SENSORS & SOFTWARE

Monitor Critical Assets and Prevent Failures Before They Happen

UpKeep Edge combines industrial-grade sensors with a connected platform that alerts your team the moment something’s off, so you can stay ahead of costly breakdowns.

PREDICTIVE MAINTENANCE WITH IIOT SENSORS

What If Your Assets Had 24/7 Protection?

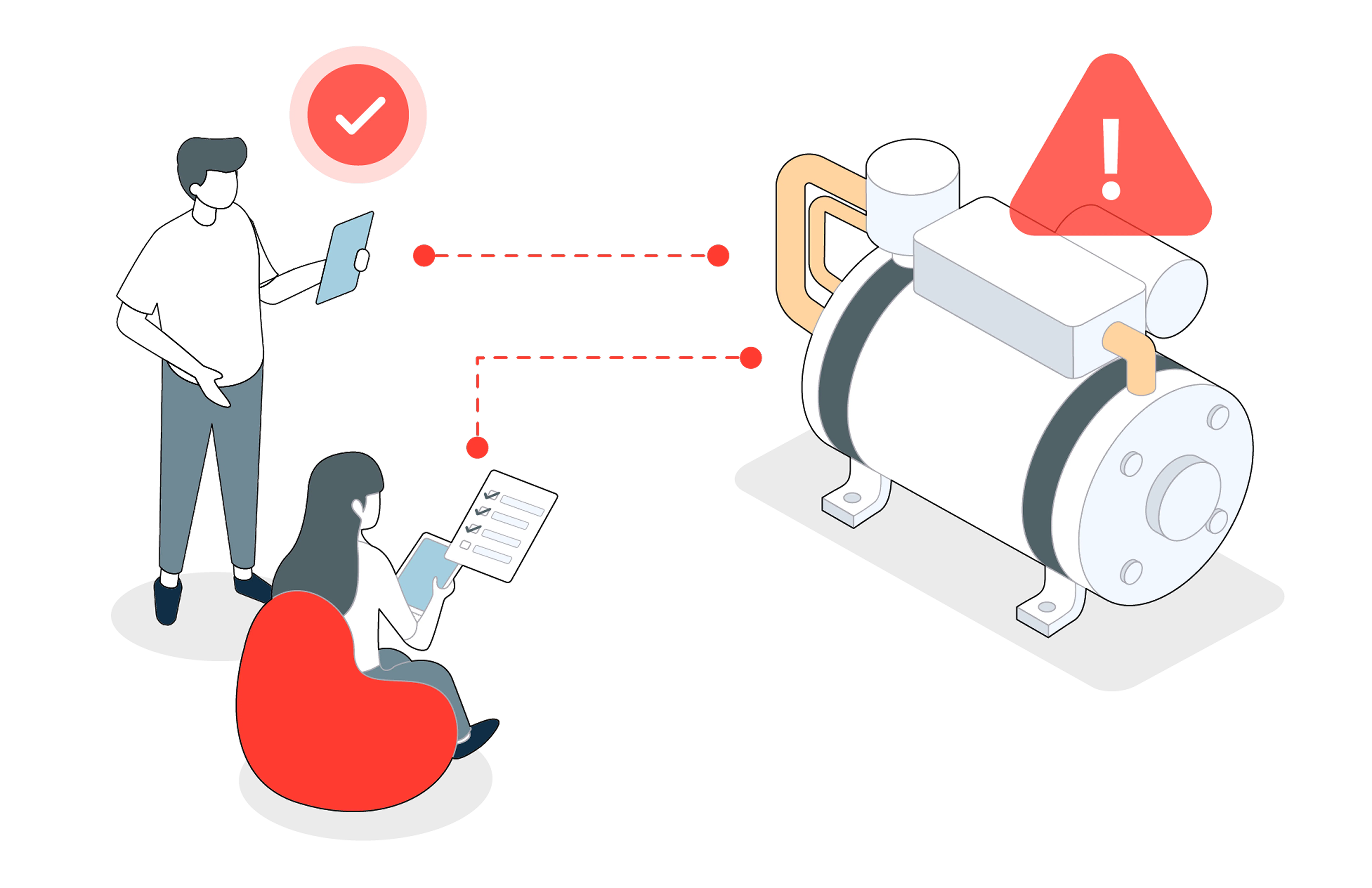

Traditional maintenance relies on scheduled inspections and reactive repairs. UpKeep Edge changes that with continuous IIoT sensor monitoring that detects temperature spikes, vibration anomalies, and pressure changes in real time. Your team can take action before failure hits.

Stop Surprise Failures Before They Happen

UpKeep Edge monitors your critical assets 24/7, detecting anomalies before they become costly breakdowns. Get instant alerts and automated work orders so your team can act fast.

Eliminate Dangerous Manual Inspections

Stop sending technicians into hazardous areas to check equipment. Let wireless sensors do the dangerous work while your team stays safe.

No Data Scientists Required

Pre-configured sensors and intuitive dashboards mean your frontline team can start monitoring assets in hours, not months.

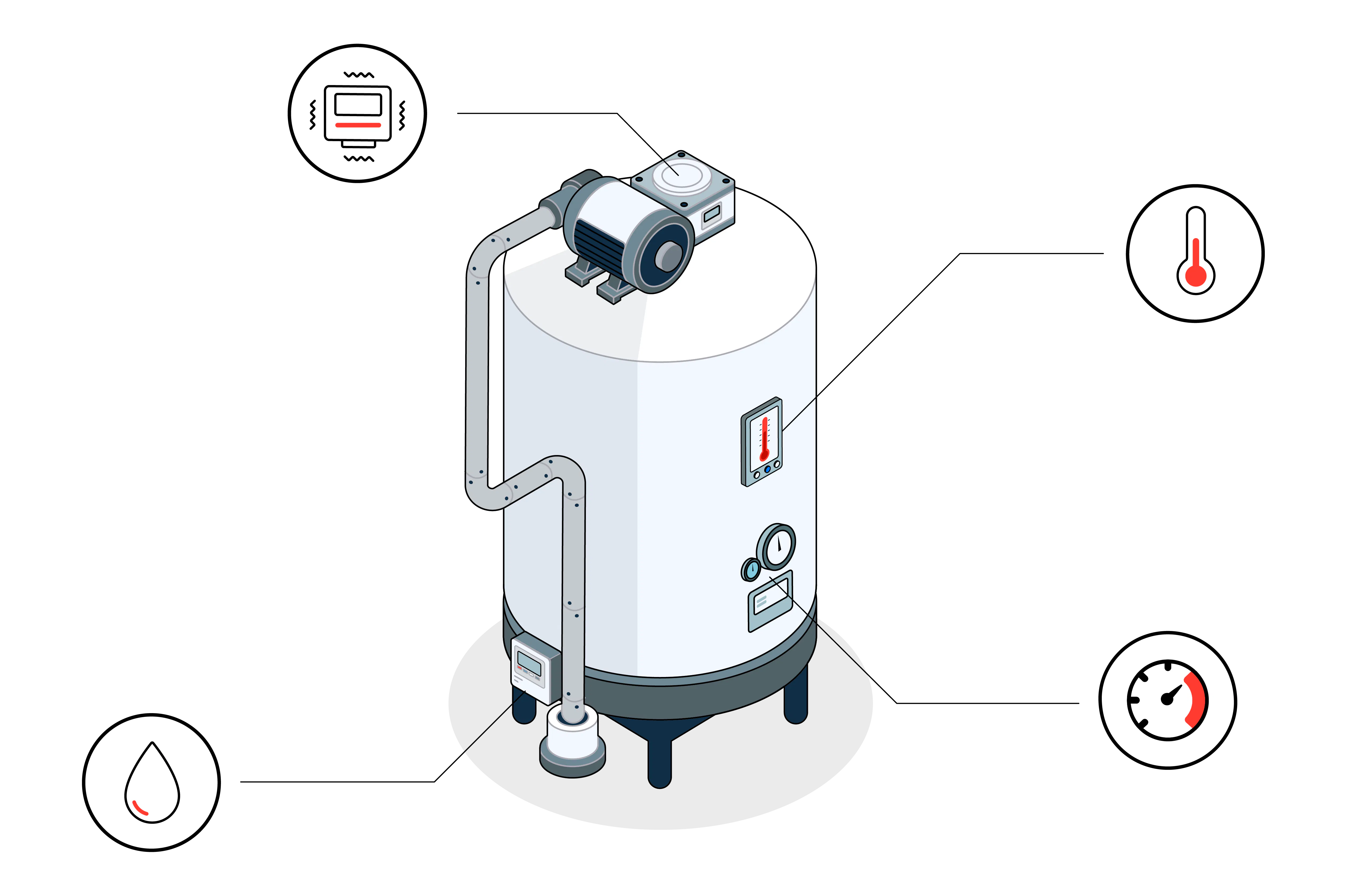

INDUSTRIAL IIOT SENSORS

Monitor Every Critical Asset with the Right Sensor

UpKeep Edge supports a complete range of wireless IIoT sensors designed for industrial environments. From temperature monitoring to vibration analysis, our sensors help you prevent failures, maintain compliance, and keep operations running smoothly across HVAC systems, motors, compressors, and production equipment.

Temperature Sensor

Keeps equipment within safe operating ranges

- Protects against overheating and ensures compliance with safety standards.

- Common Uses: HVAC, boilers, compressors

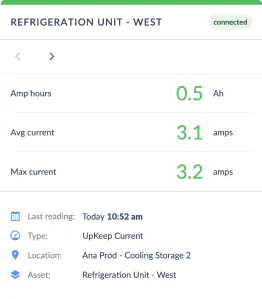

Current Sensor

Monitors electrical current to prevent downtime

- Tracks energy usage and equipment draw to spot issues early.

- Common Uses: Motors, panels, production lines

Vibration Sensor

Detects imbalance, wear, and misalignment

- Helps avoid costly breakdowns by monitoring critical components.

- Common Uses: Motors, bearings, pumps

Pressure

Monitors system pressure for safety and efficiency

- Prevents leaks, spikes, or failures in pressurized systems.

- Common Uses: Valves, tanks, lines

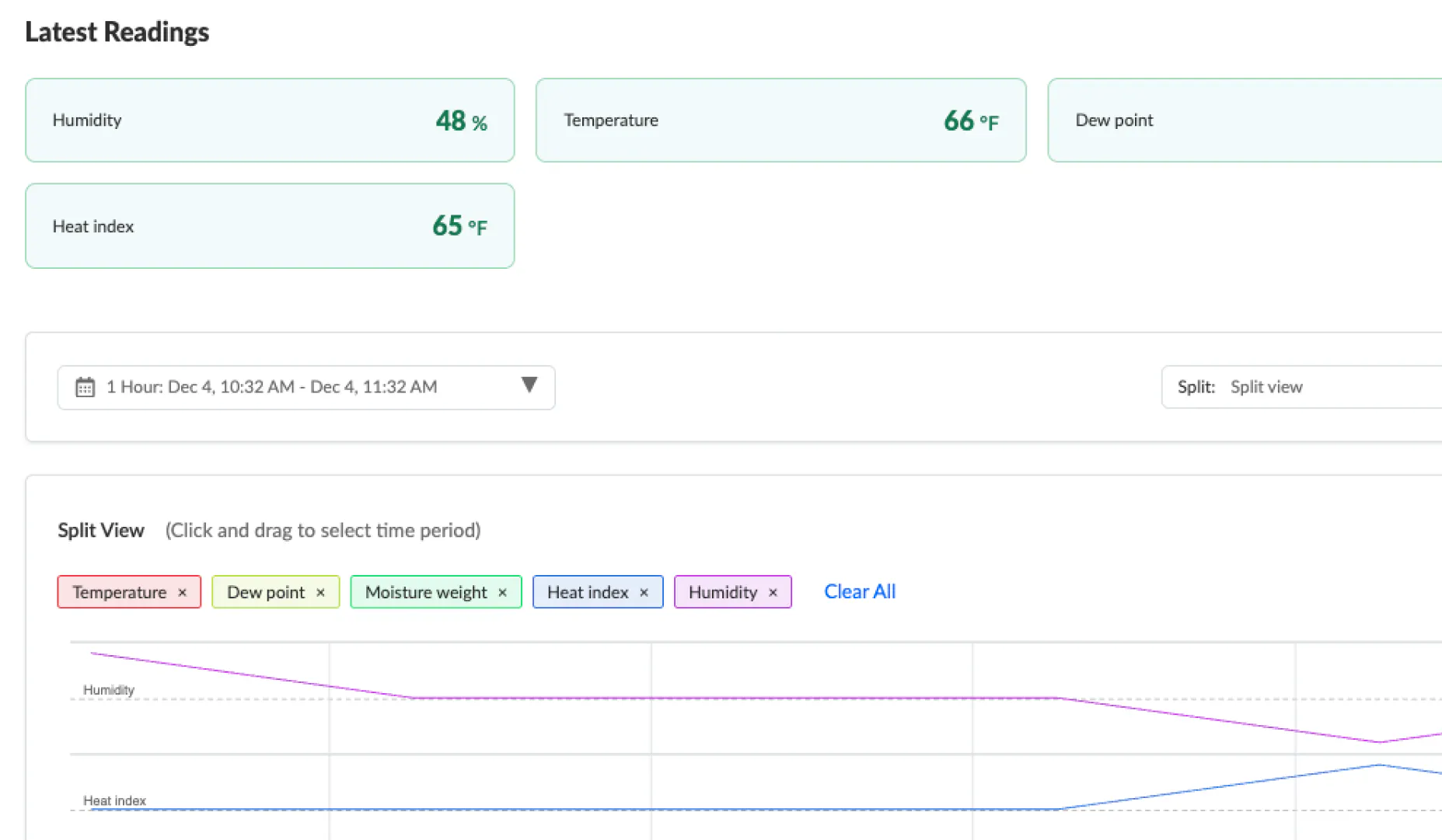

Humidity Sensor

Maintain environmental control in sensitive conditions

- Safeguards product quality and regulatory compliance.

- Common Uses: Food, pharma, chemical

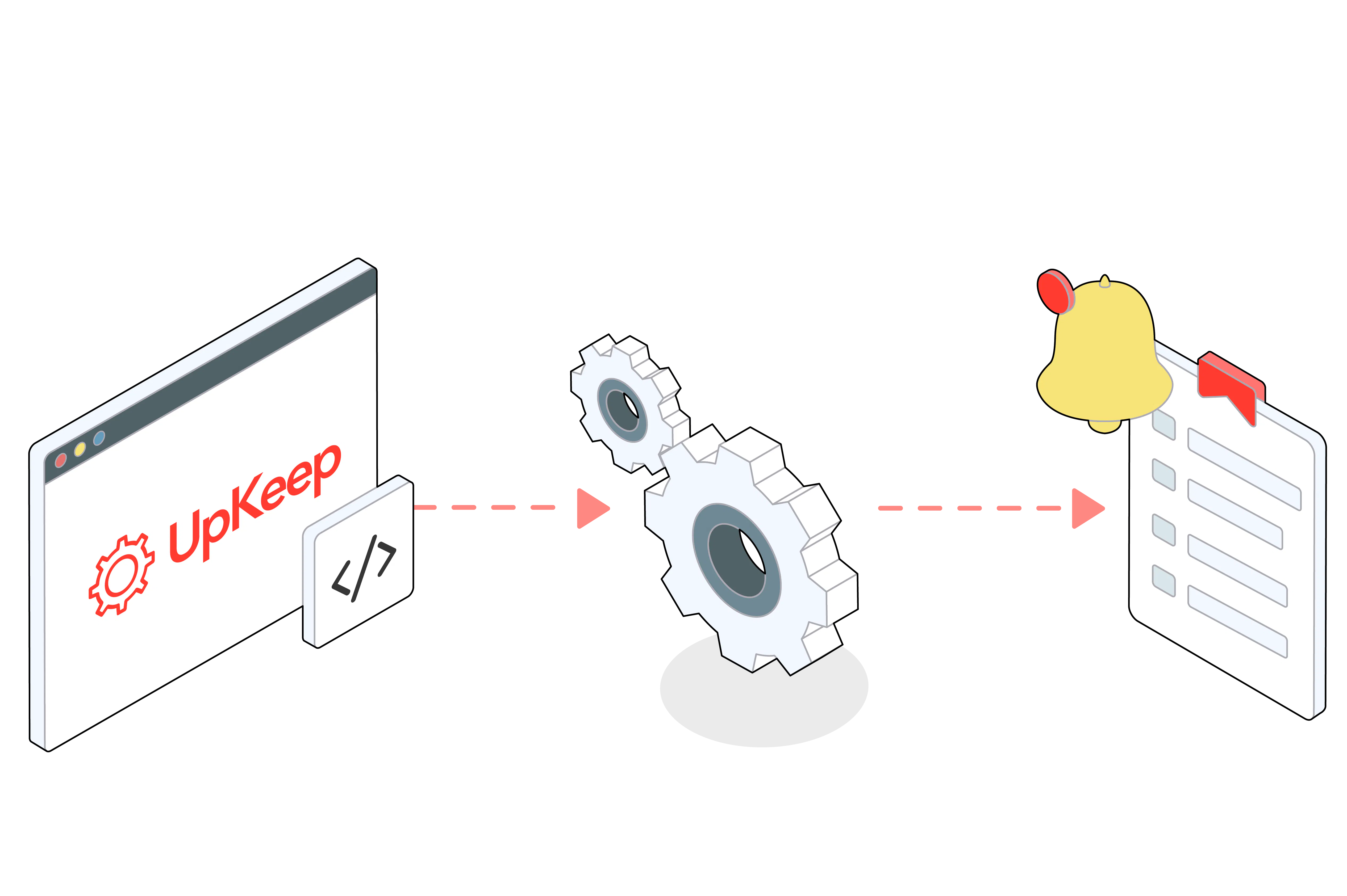

AUTOMATED MAINTENANCE WORKFLOWS

From Sensor Alert to Work Order, In Minutes

UpKeep Edge connects wireless IIoT sensors, secure gateways, and intelligent automation software to your CMMS, creating a seamless flow from anomaly detection to issue resolution. No manual data entry, no missed alerts, no confusion about next steps.

Real-Time Monitoring & Instant Alerts

Wireless sensors continuously track vibration, temperature, pressure, current draw, and more across all your critical assets. When readings exceed safe thresholds, your team gets instant notifications via mobile, email, or SMS.

Automatic Work Order Creation

No more manual data entry. Edge automatically creates work orders, assigns the right technician, and sets priority levels based on sensor readings and your predefined rules.

Pre-Loaded Repair Checklists

Technicians receive step-by-step checklists tailored to each asset and issue type, ensuring consistent, high-quality repairs every time.

Install in Hours. See Results in Days.

You don't need a data scientist. Pre-configured, wireless sensors and LTE-ready gateways stream data straight into UpKeep work orders, checklists, and notifications.

Wireless Sensors

![Temp Sensor Design]()

Sensors collect temperature, humidity, current draw, vibration, and runtime data from your assets.

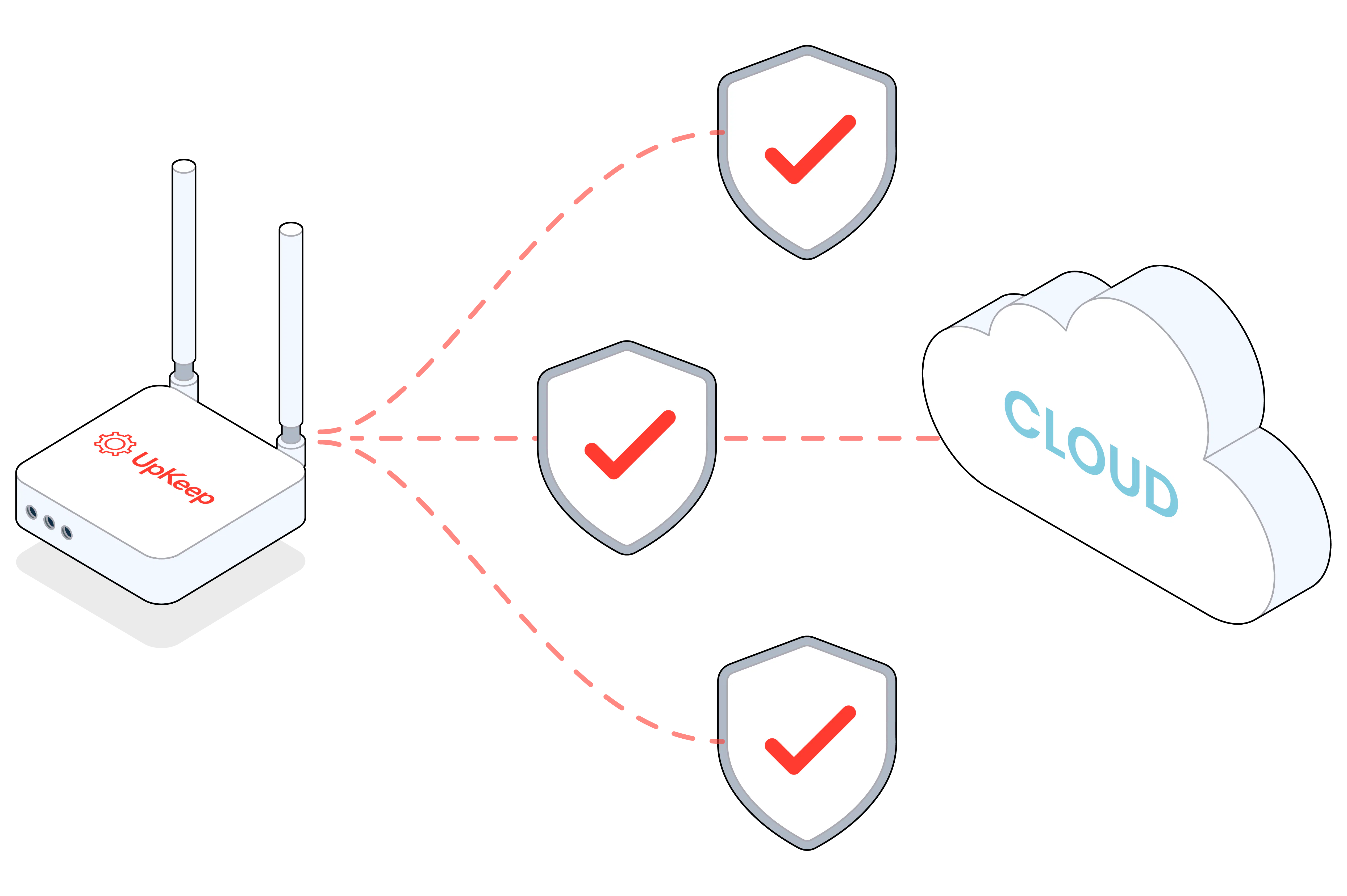

IoT Gateway

![Temp Sensor Design]()

An IoT gateway centralizes the sensor data and sends it to UpKeep’s servers. All gateways come with out of the box cellular and Ethernet connectivity.

Web Platform

![Temp Sensor Design]()

UpKeep processes the data and makes it available to detect issues, simplify preventive maintenance, and track downtime and availability.

Real Results with UpKeep Edge

Case Study

Temperature monitoring for food safety

Icon Entertainment

IIOT SENSORS & SOFTWARE FAQ

Common Questions About IIoT Sensor Monitoring

Learn how UpKeep Edge's industrial IoT sensors, wireless connectivity, and automated maintenance workflows can transform your facility's condition-based maintenance program. From installation to integration, we've answered the most common questions about implementing IIoT sensor monitoring.

Installation is straightforward and typically completed in hours, not days. Our wireless sensors require no hardwiring, and the LTE-enabled gateway connects to your network out of the box. Most teams are up and running with full monitoring capabilities within the first day.

No. UpKeep Edge is designed for frontline maintenance teams, not data scientists. The platform comes pre-configured with smart thresholds and automated workflows, so your technicians can start monitoring assets immediately without complex setup or training.

UpKeep Edge supports temperature, humidity, current draw, vibration, pressure, and runtime sensors. Each sensor type is optimized for specific use cases like HVAC monitoring, motor health, environmental compliance, and more. Our Sensor Strategy Advisors can help you determine which sensors are right for your operation.

UpKeep Edge is natively integrated with UpKeep's CMMS platform, providing seamless data flow between sensors and work orders. When a sensor detects an anomaly, the system automatically creates a work order, assigns the appropriate technician, and loads the relevant checklist—no manual data entry required.

When sensor readings exceed your predefined thresholds, UpKeep Edge instantly alerts your team via mobile push notification, email, or SMS. Simultaneously, the system creates a work order with all relevant asset information and assigns it to the appropriate technician based on your rules. The technician receives a pre-loaded checklist to guide them through the repair process.

Yes. UpKeep Edge supports multi-site monitoring with centralized dashboards and reporting. You can track asset health across all your facilities from a single platform, with location-specific alerts and work order routing.

UpKeep Edge uses enterprise-grade security protocols including encrypted data transmission, secure gateway connections, and SOC 2 Type II compliance. All sensor data is transmitted securely to UpKeep's servers and stored with industry-leading security standards.

START MONITORING CRITICAL ASSETS TODAY

You Don’t Have to Worry About What You Can’t See.

Keep your technicians and equipment safe.