Exploring the Definition, Components, and Examples of Total Productive Maintenance (TPM)

Imagine a facility that functions perfectly.

No delays due to breakdowns. No conflicting maintenance schedules. No waiting days for technicians to service equipment.

Sounds like a fabled utopia, right? What if we told you such a fantasy might be possible with a strategic maintenance practice called Total Productive Maintenance (TPM)?

In this article, we will discuss the meaning of TPM, its benefits, components, examples, and how to maximize its full potential.

What Is Total Productive Maintenance (TPM)

Total productive maintenance (TPM) is the process of maximizing equipment effectiveness through the active involvement of all supporting departments. The goal of TPM is to improve overall productivity by optimizing equipment availability.

The power behind TPM is sourced from its ability to develop cohesion for maintenance and preventive maintenance by involving all departments and people within an organization. With an organization-wide mindset focused on taking responsibility for the machines and equipment, increasing overall performance is achievable even with a limited number of resources.

The main objective of TPM is to create a system that enhances workers’ abilities to maintain and keep up with the well-being of facility assets.

And there’s no better way to do that than with a powerful CMMS like UpKeep.

UpKeep’s CMMS creates a digital ecosystem that can centralize your maintenance operations and fortify your organization's ability to enforce vital upkeep processes and practices cohesively.

By using implementing TPM processes through our CMMS, you can:

- Manage multi-location, day-to-day maintenance life cycles.

- Optimize asset utilization.

- Gain insights into real-time performance data.

- Employ an ecosystem approach.

- Bridge the gaps between maintenance, reliability, and operations.

- And more.

What Is TPM Used For?

Total productive maintenance seeks to eliminate loss resulting from poor maintenance.

By using TPM to conduct maintenance (preventive, autonomous, and corrective), mistake-proof equipment, and effectively manage safety and environmental issues, facilities can eliminate general loss in six different areas.

The six different areas of loss improved by TPM include:

- Unexpected breakdowns: Preventive, corrective, and autonomous maintenance practices may be strengthened by TPM to prevent losses and waste in lost production opportunities or yields, labor, and spare parts.

- Set-up and adjustment: When successfully implemented, TPM may streamline processes and operations to reduce or prevent losses associated with product changeovers, shift changes, or other changes in operating conditions

- Stoppage: TPM incorporates effective maintenance management practices that may prevent breakdowns, eliminate elements that slow down the process, and perfect production so defects and accidents do not occur.

- Speed: By thoroughly implementing a maintenance system that prevents breakdowns, TPM can eliminate elements that slow down the process and perfect production to reduce defects and accidents.

- Quality: Another feature of TPM is that it may detect defects in products and operations, effectively reducing costs due to waste, accidents, and mismade products.

- Equipment and capital investment: Total Productive Maintenance (TPM) may help prevent equipment and capital investment losses by identifying and eliminating sources of inefficiency and waste in production systems.

How Does TPM Work?

Maintenance, reliability, and operations workers always strive for “perfect production.”

However, this is very difficult due to unexpected problems arising even in the best-planned facilities.

Total Productive Maintenance is a set of extra measures that further tune current processes to attempt to bring a facility as close as possible to “perfect production.”

TPM frames maintenance as a business advantage—reducing downtime, waste, and equipment failure and increasing production and profit.

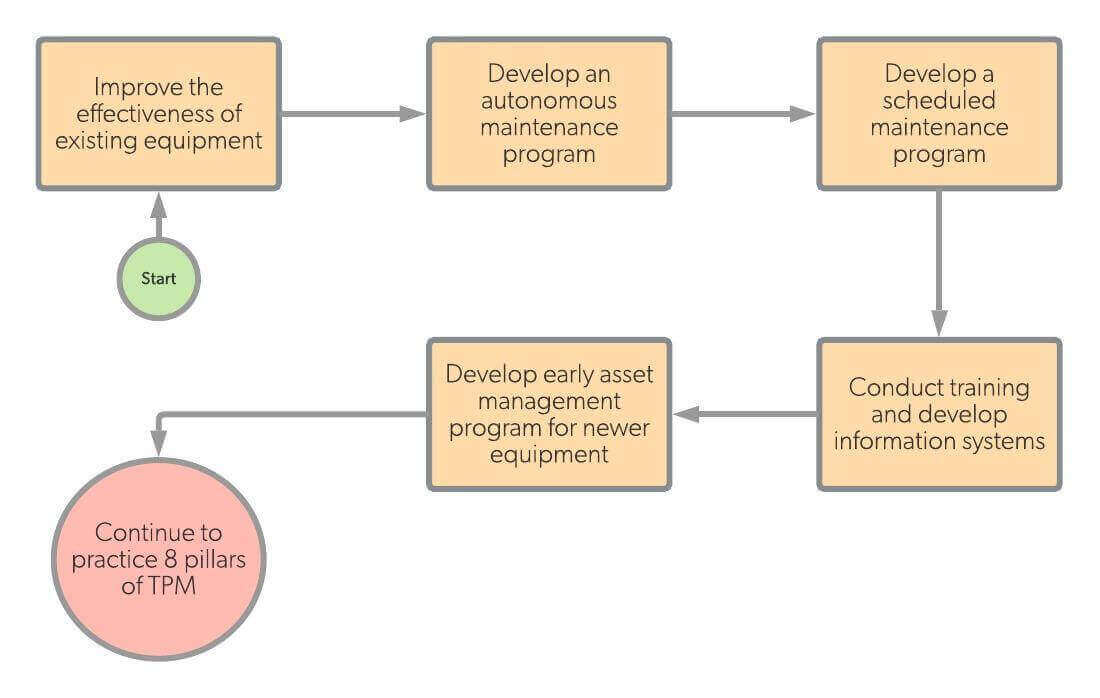

Total Productive Maintenance Workflow

TPM is an innovative concept in the manufacturing industry that evolved from preventive maintenance to adopt practices of productive maintenance, maintenance prevention, and reliability engineering.

What we now refer to as TPM has become a multi-process ingenious approach to achieve overall equipment effectiveness.

The workflow of TPM goes as follows:

- Improve the effectiveness of existing equipment.

- Develop an autonomous maintenance plan.

- Develop a scheduled maintenance program.

- Conduct training and develop information systems.

- Develop an asset management program for newer equipment.

- Continue to practice and enforce the 8 pillars of TPM.

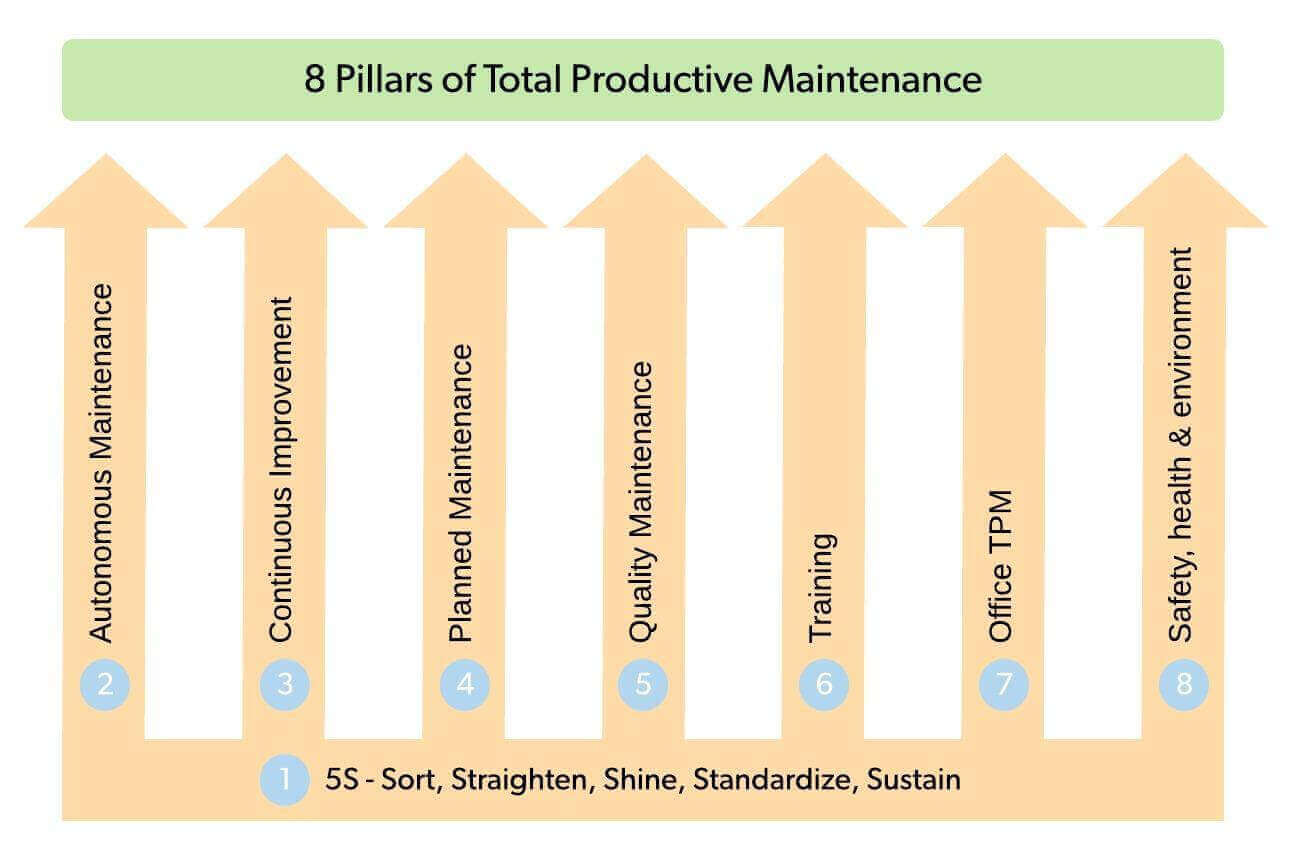

The 8 Pillars of TPM

#1: 5S Principles - Sort, Straighten, Shine, Standardize, and Sustain

Just like a physical structure starts with a grounded framework, building a robust TPM process requires a strong foundation in the form of the 5S principles.

The 5S principles are a set of workplace organization methods simplified into five basic steps:

- Sort: Sort tools, equipment, and materials to identify which items can be discarded.

- Straighten: Straighten and set things in the proper order to reduce unnecessary motion and efficiently travel between working groups and locations.

- Shine: Shine refers to performing necessary housekeeping to clean up the work area.

- Standardize: Standardize and schedule activities to systematically form the habits to keep the workplace organized.

- Sustain: Sustain the process and principles for long-term applications.

The 5S approach provides a systematic process for cleaning the workplace uncovering underlying problems and challenges. It’s an essential basis for the following seven pillars of TPM because, without it, the initiative will suffer from disorganization, indiscipline, and inefficiency.

#2: Autonomous Maintenance

TPM enforces the idea that the people using the equipment might be the best individuals to handle maintenance tasks and equipment care.

Empowering operators to work on small maintenance tasks allows maintenance teams to focus on more specialized assignments. In addition, operators can effectively reduce downtime by immediately solving issues involving breakdowns and organizing scheduled maintenance around planned downtime.

#3: Continuous Improvement

Also known as the Japanese term Kaizen, continuous improvement promotes the attitude of progressing toward zero losses and zero defects. Through minor but continual tweaks to processes, the overall effectiveness and efficiency of the organization are developed.

#4: Planned Maintenance

Planned maintenance activities are essential to preventing equipment breakdown. They involve periodically evaluating the condition of equipment to prevent deterioration and mechanical failures proactively.

UpKeep allows you to navigate planned maintenance through:

- Work order management and auto-generation

- Asset information centralization

- Data analysis and reporting

- Integration with DataHub and other maintenance management tools

- And more

#5: Quality Maintenance

Manufacturing processes aim for zero-defect production to ensure customer satisfaction.

Standards for superior quality and checks on whether the standards are being met should be in place. Quality maintenance aims to identify any possible causes of deviations from zero-defect production.

An essential component of the quality maintenance pillar of TPM is root cause analysis. When equipment fails, it is vital to identify and resolve the issue quickly. However, root cause analysis takes this further by identifying and documenting the underlying problems to prevent further issues.

UpKeep upholds quality maintenance by allowing technicians to access essential maintenance information, such as:

- Manufacturer warranties

- Machine manuals

- Maintenance history

- And more

The key to successful maintenance programs is keeping all maintenance participants knowledgeable and informed. With UpKeep, you can keep up with vital facility information and quickly resolve costly breakdowns.

#6: Training

The idea of TPM is that everyone does their part to contribute to the overall productivity of the production process. Proper training is required to equip each member with the theoretical and practical know-how of working with machines and equipment to achieve optimum performance and build each member's competence.

#7: Office TPM

The administrative department, which works behind the scenes, plays a vital role that's often overlooked. Like the rest of the production teams and processes, the management and administrative functions are also subject to productivity improvement. This includes identifying and eliminating losses and contributing to the overall performance of the plant.

#8: Health, Safety, and Environment

The last of the eight pillars of TPM focuses on creating a safe workplace.

This pillar's essence is realized when actively applied to each of the other components. Successful implementation of this pillar may contribute to a secure and hazard-free workplace.

Total Productive Maintenance Examples

The ideals encouraged by TPM are deeply rooted in people's involvement. The main factor that drives its success is the proper attitude exhibited by the management, maintenance staff, and operators alike.

Let’s look at a few case studies that exhibit successful TPM implementation.

Toyota

TPM developments were first seen in Japan, with Toyota being one of the first companies to receive TPM certification.

The philosophy behind TPM was pivotal in achieving Toyota’s Just In Time level of service and reliability in its production facilities. Seiichi Nakajima, regarded as the Father of TPM, describes this philosophy in a quote: “TPM is the making of products through the making of people."

Cervecería Cuauhtémoc Moctezuma

Another TPM success story occurred inside one of the largest beer brewers in Latin America, Cervecería Cuauhtémoc Moctezuma (CCM). The principles of TPM, born in Japan in the 1970s, are alive and thriving in all of the company’s six plants in Mexico.

Explaining the meaning of TPM and how CCM applies it within the organization, plant maintenance manager Manuel Sanchez says, “It means we are all responsible for guaranteeing the total effectiveness of the equipment—maintenance, production, top management, human resources… everyone.”

How UpKeep Can Help Your Organization With TPM Implementation

Total Productive Maintenance (TPM) is about maximizing equipment effectiveness through the active involvement of all supporting departments. UpKeep, a mobile-first CMMS platform, plays a crucial role in facilitating TPM implementation and success by allowing organization administrators, operators, and technicians to:

- Create and implement effective preventative maintenance plans.

- Establish standard maintenance practices.

- Gain insight into the effectiveness of TPM strategies.

- Communicate with other involved parties.

Like TPM, one of UpKeep's main goals is to create a system that empowers equipment operators by allowing them to manage maintenance themselves. Our powerful tool is what your operators need to uniformize maintenance standards and improve operations.

Learn more about our powerful CMMS tool today.

Want to keep reading?

How would I implement a total productive maintenance program?

Total Productive Maintenance [Pillars & Benefits of TPM] - UpKeep

4 Ways to improve productivity for maintenance teams

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)