Author

Amissa Giddens

Filter your results

Showing 21 of 48

Foster a Flourishing Maintenance and Reliability Workplace Culture

When we think of a maintenance and reliability culture, we often think of the processes, tools, and technologies required to foster greater efficiency and reliability of a company’s assets. While...

View Article

Leadership Strategies in Maintenance and Reliability

Scores of business books and training programs are available to help organizations create their long-term vision. Why? Because successful leaders in maintenance and reliability must exhibit a visionary approach by...

View Article

How to Build and Understand the Essence of Reliability Culture

Developing a reliability culture plays a pivotal role in achieving and sustaining excellence in today’s manufacturing facilities. This culture goes beyond mere processes and procedures; it encapsulates a mindset, a...

View Article

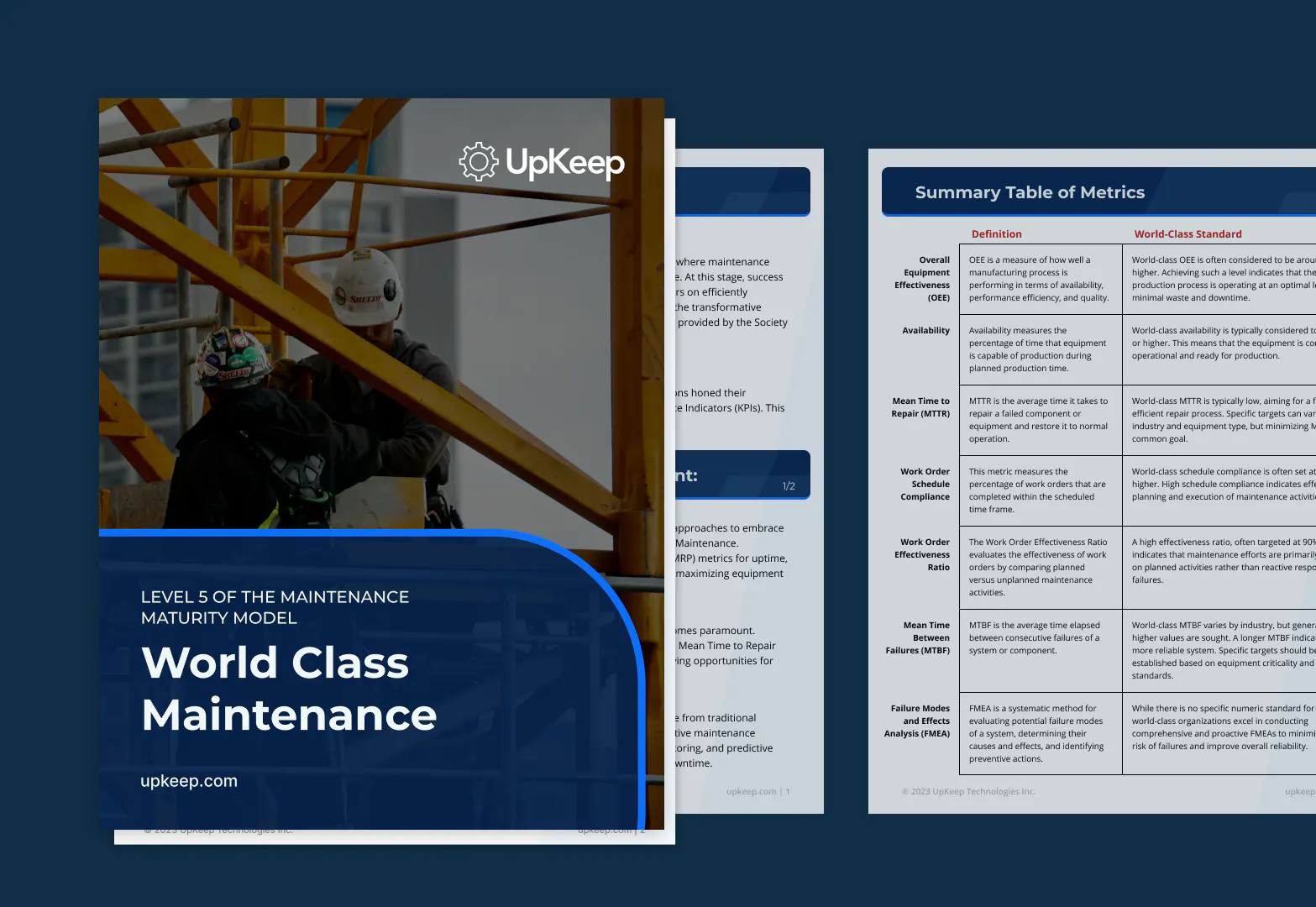

The Final Level of the Maintenance Maturity Model: World-Class Maintenance

By the time you've reached Level 5 of the Maintenance Maturity Model, you're truly ready to achieve world-class maintenance. At this stage, your entire maintenance system will be centered on...

View Article

Revolutionizing Maintenance: The Case for Digital Work Order Management

In a world where we all use devices nearly every hour of every day, it’s hard to imagine doing anything manually anymore. Yet a vast number of small- to medium-sized...

View Article

UpKeep's Dynamic Duo: Ambassador Program and Pledge Pros Podcast Unveiled

We’re excited to announce our latest initiatives: the Ambassador Program and the Pledge Pros Podcast. These programs serve as cornerstones in fostering industry connections, providing education, and enhancing the maintenance...

View Article

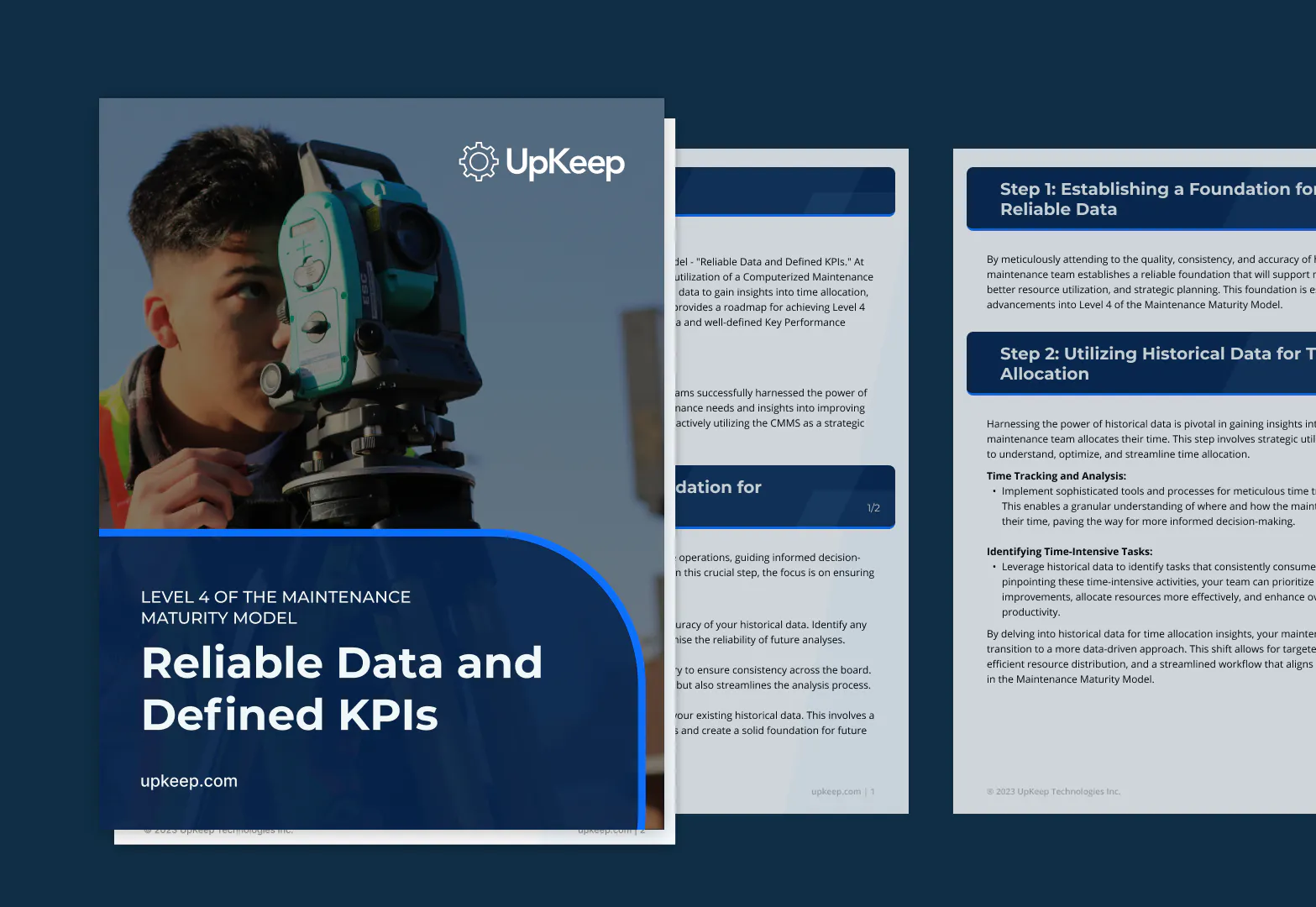

Embracing Level Four of the Maintenance Maturity Model: Reliable Data and Defined KPIs

y the time you’ve reached level four of the Maintenance Maturity Model, your organization has already made tremendous progress in streamlining operations and workflows and gaining efficiency. You’ve abandoned inefficient...

View Article

Moving to Level Three of the Maintenance Maturity Model: Successful CMMS Adoption

Companies who have successfully moved beyond the first two stages of the Maintenance Maturity Model, which included both the transition away from pen, paper, spreadsheet and other manual systems as...

View Article

How to Boost Maintenance Team Morale: Strategies for a Productive and Happy Workforce

Maintaining high morale within a maintenance team is crucial for ensuring productivity, job satisfaction, and overall success. A motivated and engaged team is more likely to handle challenges efficiently, stay...

View Article

Ready for Level Two of the Maintenance Maturity Model: CMMS Implementation

At this stage, you’re ready to learn the nuts and bolts of making the transition to a CMMS. By the end of this level, you’ll be well on your way...

View Article

UpKeep Dominates in G2's Winter Assessment for Outstanding CMMS Software Performance

As we wrap up the year with a strong quarter, UpKeep, a leading CMMS solutions provider, continues to dominate the market. They've earned recognition in various categories of G2's Winter...

View Article

2024 Usage Guide for CMMS: Maximizing Efficiency and Reliability

Today, nearly all large and mid-sized manufacturers use some sort of CMMS to track and manage their maintenance activities. However, a surprising number of smaller companies are still using pen...

View Article

Embracing Level One of the Maintenance Maturity Model: From Pen and Paper to CMMS

The vast majority of people today rely on technology in just about every aspect of their life. Devices, apps, and software make us more efficient, help us communicate effectively, and...

View Article

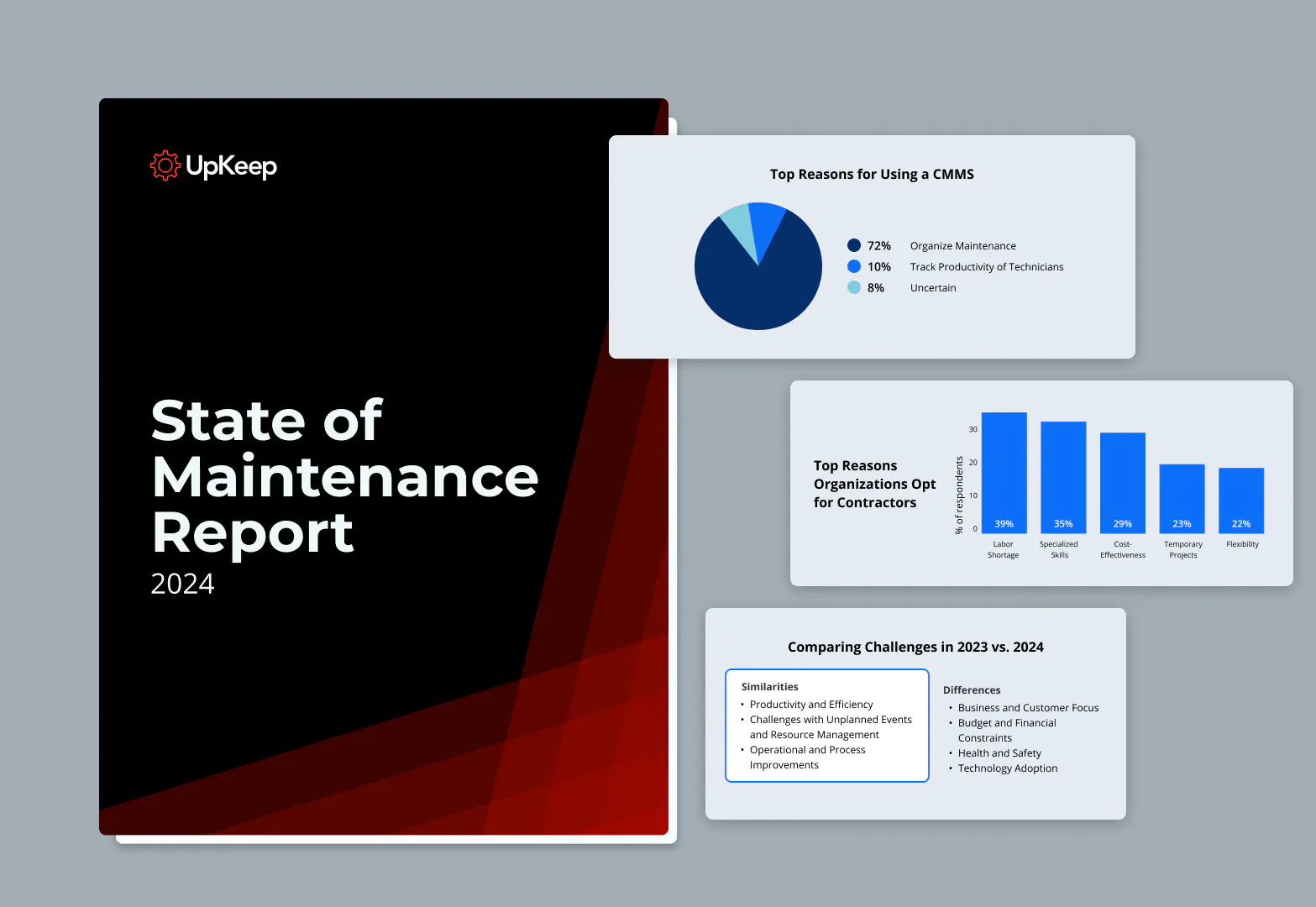

2024 State of Maintenance Report Reveals Industry Highlights and Challenges for the Year Ahead

The State of Maintenance Report 2024, unveils insights from maintenance and reliability executives worldwide, with a focus on U.S.-based small to mid-sized companies. Key findings include a positive outlook with...

View Article

Reliability Resolutions: Setting Maintenance Goals for a Successful New Year

It’s that time of year again! As we approach the end of 2023, many of us are making personal New Year’s resolutions. Take that fresh-start attitude to your maintenance and...

View Article

UpKeep's New Product enhancements: A Closer Look

In the ever-evolving landscape of maintenance management, UpKeep continues to lead the way with its commitment to enhancing user experience and functionality. The latest product improvement updates bring a host...

View Article

Reliability Centered Maintenance (RCM): A Deep Dive into Best Practices

Reliability centered maintenance (RCM) has been around for decades, but there’s often still some confusion about how to implement RCM and best practices for those who have not adopted this...

View Article

Festive Downtime: A Guide to Holiday Maintenance Best Practices

In some industries, the end of the year means a business boom, as retailers ramp up for Black Friday and the holiday shopping season, the entertainment industry gears up to...

View Article

The Role of Training in Maintenance: Empowering Teams for Success

Every successful company understands the importance of a solid training and development program. Unless employees and technicians know how to do their jobs well and are motivated to continue to...

View Article

Workforce Diversity in Maintenance: Benefits and Strategies for Inclusion

Today, DEI goes far beyond simple demographics, extending to include different perspectives, experiences, and skills. Being able to embrace diversity of all aspects of the human person can broaden the...

View Article

Mental Health and Well-Being in Maintenance

Within the maintenance industry, where the focus is often on keeping equipment running and repairing assets, the mental health and well-being of the maintenance team is often overlooked. Just like...

View Article

Page 1 of 3

- ...

Filter