What Is the Theory of Constraints?

The theory of constraints looks at what's holding back an objective in manufacturing from achievement and supercharges a team to make necessary changes to revitalize progress.

For example, Mazda applied the theory of constraints to transform its business to meet the needs of consumers. Targeting those impacted by financial losses due to the recession, Mazda wanted to provide quality products that could be affordable. Mazda then developed advanced technology that provided low fuel consumption from an internal combustion engine that would rival a hybrid engine.

Some struggles stay the same for companies, no matter what industry they are in, where they're located, and who are working for them. These fundamental needs spawn most of the so-called “management fads” that populate many different websites, news feeds, and other sources of information.

While management fad is a term that is generally used in a derogatory sense, everything that is labeled this way has a basis in reality and the potential to change a company in a real, fundamental way. One of the best recent ideas that have been gaining traction is the theory of constraints.

In this article we will cover:

- The goal of the theory of constraints

- Application of the theory of constraints

- The theory of constraints five focusing steps

- Pros and cons of the theory of constraints

- Examples of the theory of constraints

- Implementing the theory of constraints in your business

What Is the Theory of Constraints?

The theory of constraints is a management strategy that focuses on improving the most important and limiting factor (the “constraint”) until it is identified and resolved. This factor may also be referred to as a bottleneck, particularly in manufacturing.

The process is based on the philosophy that all complex systems are made of multiple activities that are all linked together. This chain of events depends on each event, one of which is the bottleneck/constraint/weak link.

When that link is eliminated, the entire process according to the theory of constraints becomes streamlined, more efficient, and more reliable. In a company-wide strategy, the processes move from link to link until all links are streamlined and efficient.

Instead of eliminating waste, the theory of constraints works from an increasing sales point of view. This viewpoint directly impacts the goal and the applications of the theory of constraints.

The goal of the theory of constraints

The simplest definition of the goal of the theory of constraints is profit, both long-term and short-term. In this process, multiple sub-processes such as the Five Focusing Steps and Throughput Accounting are used in order to discover, improve, and eliminate the different constraints that companies face.

In order to achieve this goal, the theory of constraints rests on prioritizing improvement activities above everything else. The top constraint is always the problem that must be solved first.

Typical theory of constraints applications

The theory of constraints can be used in a lot of different applications across-the-board. Some common ones include:

- Project management

- Production management

- Sales and marketing

- Distribution

- Supply chain management

When many people first discover the theory of constraints, they think it can only be applied to plant management and other applications mentioned in the theory of constraints founding document, The Goal, by Dr. Eliyahu Goldratt. While those are common examples given in the book, the process can be applied to many different things.

Here’s a look at that process, its core principles, and some of the pros and cons of this system.

The theory’s processes

Unlike other processes, the theory of constraints rests primarily on its core principles. These principles, in turn, are a set of processes that focus on the constraints in question. The biggest pillars are the Five Focusing Steps and Throughput Accounting.

Understanding these pillars enables companies to understand the processes behind implementing the theory of constraints.

The Five Focusing Steps

These five steps are the foundation for identifying and removing constraints in this methodology. It’s a cyclical process that can start at one specific point: identifying the constraint. The Five Focusing Steps are:

- Identify

- Exploit

- Subordinate

- Elevate

- and Repeat.

This is a continuous cycle that is applied across all assets and constraints when companies commit to using the theory of constraints as a meeting in strategy. In other cases, it may be a one-off done to a particular asset to test the viability of the strategy for a company's needs. In either case, the five focusing steps are a great beginning to a cohesive theory of constraints strategy.

The thought processes

The thought processes mentioned here are a fancy way of referring to three questions that must be answered when you're using the theory of constraints. These are:

- What needs to be changed?

- What should it be changed to?

- What actions will accomplish this?

In some cases, companies have used different, smaller strategies to answer these questions. More common strategies used include decision trees, diagrams, and other methods of sorting through data.

Throughput Accounting

The final pillar of this system is throughput accounting. Briefly put, throughput accounting is an alternative accounting system that prioritizes eliminating traditional issues that plague accounting, such as accumulating too much inventory and so-called “paper profits.”

Three different metrics are used to determine how well companies are using throughput accounting. The first one is throughput, which is the rate at which customer sales are generated minus fully variable costs. These variable costs do not include labor, unless they can be fully tied to produced inventory.

The second metric is investment, that is money that is locked into physical things. And the last metric is operating expenses, which are fairly straightforward.

In the theory of constraints schema, most management decisions are based on increasing throughput, reducing investment, and reducing operating expenses in that order. The majority of the effort goes into increasing throughput.

Putting it all together

The end goal of all of these systems, rules, and cycles is to focus less on cutting expenses and more on creating sales. That’s the essence of the theory of constraints.

While it may seem complicated, especially when reading about this theory, the core idea is one that companies have always had in some shape or form. You can either cut expenses or increase sales. Ideally, you would do both. The theory of constraints puts increasing sales first and foremost.

That being said, every company is wildly different and not all strategies work in all places. Let's look at the pros and cons of the theory of constraints and where it would work best.

Pros and cons of the theory of constraints

Before we get started, it's important to realize that these pros and cons may not be applicable in all situations. Also, the theory of constraints methodology is not always at fault and may not be the problem. With that being said, here are the typical pros and cons of the theory.

Pros

There's one thing that the theory of constraints is best at and that is it improves communication between departments. By its very nature, this strategy depends on different departments and sections of a company talking together to determine where the constraints are and work together on solving them. For companies that are struggling with styling, disconnection, and other communication issues, the theory of constraints may be a great help.

This process also excels at improving short-run capacity decisions, understanding and editing older company processes, and avoiding localized department optimization. The focus is on the company as a whole, as opposed to improving a department at a time. It takes a very organic approach to the events that happened on a day-to-day basis on a production floor and in the office at the same time.

Finally, it's something new. Sometimes organizations need a new strategy to shake them from top to bottom and to get them back on track. The theory of constraints is one such strategy that is very good at revitalizing large organizations and getting them all to work together again.

Cons

For every pro, there's generally a con behind it. Improved communication between departments and a heavy focus on constrained areas can lead to neglect of areas that do not face constraints. This focused concentration can also center around problem areas and forget about areas that are in need of reward or recognition.

This methodology also promotes a desire to reduce capacity and production. Because there is so much focus on trimming down excess inventory, it's tempting to simply stop making things in order to reach the new, lower quota. While the theory of constraints focuses on selling all of your inventory as a method of reducing access, there's always the reality that there's another way: cutting back. And that needs to be avoided.

The theory of constraints is also a short-term, rapid solution to constraints. If not carefully watched, the long-term is easy to forget about when companies start using these strategies. Because the long-term will become the short-term quicker than anybody cares to admit, these tendencies do negatively impact the company. Examples include neglecting to release new products, less attention to the resource and development sectors, and overall long-term improvements.

In general

All of these aspects, both positive and negative, have a place and time. Some companies will find a lot of good comes from the theory of constraints. Others will have a harder time leveraging this method.

What’s great about this system, in particular, is that it doesn’t have to be a company-wide change. Try it out in a small department or integral piece and see what it may offer you!

Theory of Constraints Examples

Now let's move on to some examples of the theory in practice. Here, it's split up by industry but a few general things apply across the board. First of all, the processes outlined above are the same no matter what the industry. The application is what differs.

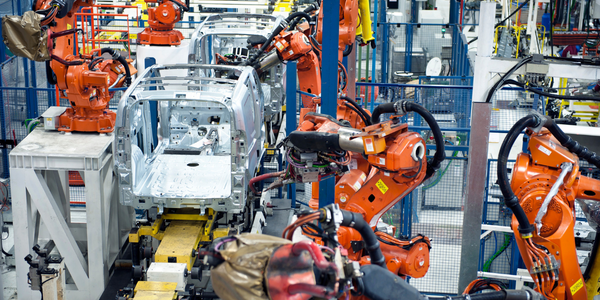

It's also important to note that the theory of constraints works at its best in different situations depending on the industry. For example, manufacturing plants may see the most improvement when they commit to the theory of constraints if they apply it first to their production lines, machinery, and other common sources of bottlenecks.

On the other hand, a maintenance company may see the most improvement when they apply these practices to paperwork, regulations, government guidelines, and other industry-specific constraints. Here are examples of the theory of constraints in the manufacturing, maintenance and healthcare industries to get you started.

Manufacturing

It's not much of a surprise that manufacturing as a whole has seen great results from the theory of constraints. It's particularly useful when applied to large assets, production lines, and other areas crucial to the company's success. However, these same areas are very prone to bottlenecks, such as equipment downtime. One notable example is Dr. Reddy’s Laboratories in 2014. Facing down a significant amount of backorders and low supplier ratings, they needed a change.

The theory of constraints enabled them to boost their ratings, fill their backorders, and eventually paved the way to them receiving a recent best supplier award. They continue to use it to this day.

Maintenance

Maintenance companies don't rely as much as manufacturers on heavy assets and production lines. However, they do have to balance the needs of many different facilities at the same time. They may also be a department within a larger company, with their own goals and methods that are not necessarily the same as other departments and don’t have a highly-visible direct impact on the overall company.

The theory of constraints bridges the gap between a maintenance department and the rest of the company. For maintenance-oriented companies, it prevents siloing, improves information transferences, and cuts through the fluffy tasks that are done simply because someone said that they ought to be.

Healthcare

Healthcare industry companies of all sorts struggle with the mountains of paperwork that they must manage, sort, and utilize on a regular basis. That's a whole lot of constraints right there! The theory of constraints is a great way to start out what has to take time from what is taking time. This can be invaluable when it comes to paperwork and all of its attendant problems.

Depending on what part of the healthcare industry companies are in, they may find additional benefits, such as increased communication and connection that are offered to companies. It's a flexible system that can be adjusted to a lot of different needs, just like healthcare.

Implementing the theory of constraints in your business

The best way to implement the theory of constraints in any given business is to start with the five focusing steps. It's a straightforward cycle that can be easily scaled up or down according to your needs. The cyclical nature of these steps makes it so that there's no need for huge, overwhelming company-wide change, yet if the system works, it’s easy to scale it up.

That being said, what are some simple steps for those who do not want or cannot freestyle such a change on their own?

Walking through the different steps

The theory of constraints is one of the easier strategies to implement because it is so clearly outlined in the five focusing steps and in thorough accounting. Here are some questions to get you started on the five steps.

- Identify: What is the current bottleneck or constraints that we are struggling with the most?

- Exploit: What are some quick improvements you could make today, with the resources at hand? What are some improvements that will take a longer time?

- Subordinate: What can we stop doing in order to make those improvements?

- Elevate: Is the problem the first priority or are other things getting those resources, time and effort? Are we elevating the issue in question above everything else or is it still an afterthought or nuisance that we have to deal with?

- Repeat. What’s the next constraint on the list?

That’s all you need to get started. What else do you need for a smooth transition to using the theory of constraints on a department or company level?

Getting buy-in from other managers and departments

After the initial testing phase/tryout, you may want to scale the theory of constraints to fill your overall department or company needs. This is highly dependent on raising and getting support from other managers and leadership throughout the company.

Some things to keep in mind during this process include:

- Talk to the people who know your assets backed. They'll know where the bottlenecks are and they will tell you if you give them an opportunity!

- Make sure that people understand what the theory of constraints is. A lot of people look at something new and think that it's going to create more work down the line. This isn't always the case and should be made clear from the start.

- Understand that changing the way people think takes time. A lot of time is standard for most new management strategies.

- Finally, it may not be for you. The theory of constraints is a great strategy for many companies, but it may not work for your needs. One of the most common mistakes during this whole process is getting too invested in a theory or strategy that does not work for you. It's a good thing to keep in mind as you work to create success.

Pulling it all together

After the groundwork has been laid, it's time for everything to work out--at least in theory. What are some troubleshooting guides for the most common problems that arise during the implementation of the theory of constraints?

First of all, the entire theory rests on the five focusing steps and thorough accounting. They should be the first two areas that you check when things start going wrong. In general, if one of the stops is forgotten, it will affect all the rest of the steps.

Next, throughput accounting is not a complete substitution for regular accounting. Both need to be present and monitored in your company, even after you have committed to the theory of constraints.

Finally, if something's not working, investigate it and go back to the basics. Have each of the five steps been accomplished? Are you treating the steps as a cycle? Are you aware of all of the constraints inherent to this theory and acting accordingly?

Many times, these small bumps seem much bigger than they actually are. As with most strategies, the important thing is to keep going.

In conclusion

The theory of constraints is a great method to revitalize companies and their processes. It focuses on moving quickly through the normal, everyday clutter that drags down employees, managers, and executives by offering solutions to the most immediate problems. This makes it ideal for companies who are older, struggling with tedious processes, or who don't have a cohesive system in place today.

On the other hand, this theory can cause younger companies to sprint too quickly through problems without thinking about the longer-term. The same things that enable companies to move quickly also tend to forget the long run. While this may not be a problem in companies where there is a sound infrastructure that simply needs to be dusted off, the theory of constraints should not be relied on as a be-all-end-all solution.

Like most management theories, the theory of constraints has a lot to offer companies today. Unlike many other strategies, it's easy to implement on a small scale in order to see if it works for your needs. Try it out today in tandem with a quality computerized maintenance management software and see where it will take you.

The sky's the limit!

Want to keep reading?

What Is Maintenance Process Mapping?

Maintenance Optimization: Optimize Planned & Preventive Maint.

How to Create a Predictive Maintenance Program

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)