SCADA: What It Is and How It Works

Efficiency, reduction of errors, downtime, and costs.

These are issues that all industrial leaders and stakeholders are concerned with. Efficiently operating plants and controlling these variables are possible with the use of resources like a SCADA system.

Learn what SCADA is, how it works, its key components, and industries that benefit from it to know how to implement this powerful resource in the day-to-day operations of your industrial organization.

What Is SCADA?

SCADA stands for Supervisory Control and Data Acquisition. It is a computer control system used to monitor and control plant processes. SCADA uses data communications, graphical user interface, and extended management to monitor systems.

SCADA systems are valuable resources to help industrial organizations:

- Maintain efficiency

- Quickly process data

- Communicate system issues

- Reduce downtime

An Example of a SCADA Application

A SCADA system could be used in a plant to make operators aware of changes in production or machine functioning. For example, when a batch of products begins to show high rates of error, a SCADA system will alert the operator.

The machine operator can then stop operation and look at the SCADA data to troubleshoot why the malfunction is occurring. Once the operator pinpoints the problem, he is then able to take measures to correct the problem quickly, without extended downtime and loss of product.

How SCADA Works

Think of SCADA as a bridge that links equipment with operators and maintenance personnel. The SCADA system requires some key components to facilitate this transmission of data from the physical equipment to the operator’s display screen. This, in turn, allows maintenance technicians to perform certain tasks or monitor asset behavior along the way.

Some typical tasks include:

- Checking sensors and other devices that may be installed at remote substations or control stations

- Tracking machine system events for future reference

- Changing the level or speed of production processes from a central spot

In essence, SCADA systems allow technicians to stay in one spot yet extend their virtual reach to many different assets, locations, and systems. The automation presented by SCADA systems allows greater efficiency and better decision-making for the management team, leading to greater productivity, increased safety, and revenue generation.

Key Components of a SCADA System

Sensors and Manual Input

Digital or analog sensors serve as measuring tools that collect data from various parts of the plant. Sensors may range from simple binary options, such as an on or off signal, to more complex tools that measure flow rate, temperature, and pressure. In addition, technicians or operators at the remote or central location can manually input data into the system.

Conversion Units

Data collected by sensors is only useful if it can be converted into a form that is easily comprehensible. Remote terminal units (RTU) and programmable logic controllers (PLC) are the devices that can translate the collected data into usable information. Since information is collected throughout an entire system, the sheer amount of data can be great.

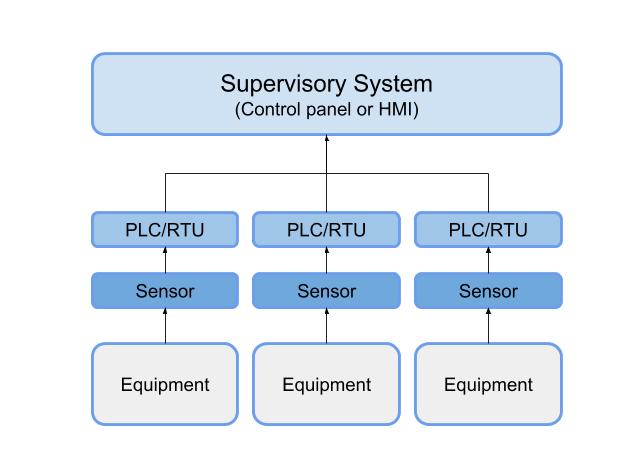

Example of a supervisory control system

Supervisory System

Data feeds that are converted by the RTUs and PLCs meet at a master unit known as the supervisory system or the human-machine interface (HMI). This interface brings useful information to the maintenance team.

At this point, one operator can have a complete picture of an entire process or system. The data is presented in an easily digestible format, and the employee can take control of certain pieces of equipment to make repairs or isolate failures.

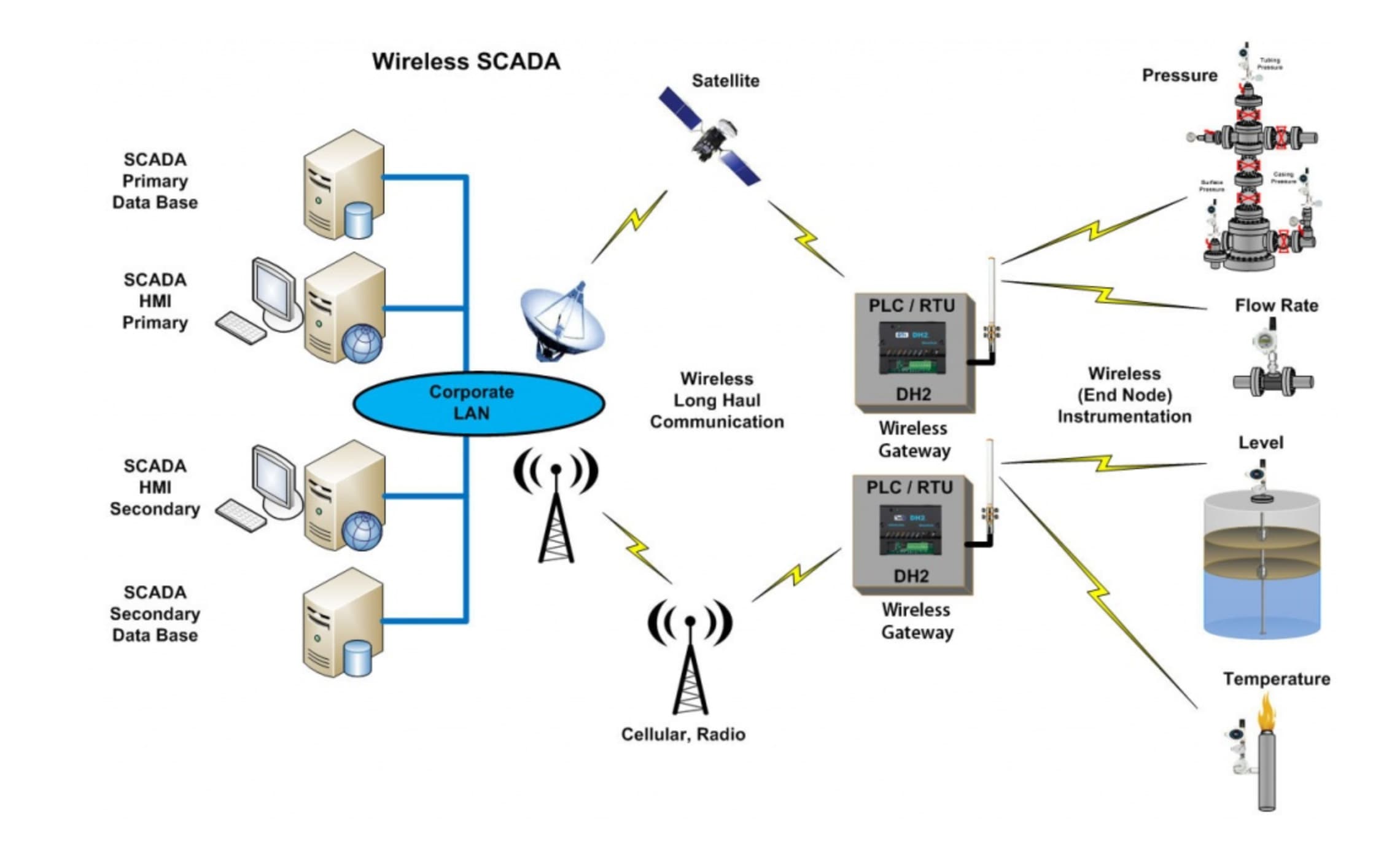

Communication Network

All the SCADA components are located throughout the plant and must be linked together by a communication network. Conventionally, telephone lines and circuits have served as this network, with newer wireless options now available that use radio waves or cellular satellites.

Who Uses SCADA?

A wide variety of companies, organizations, and businesses can use SCADA systems in order to improve efficiency, share quality data across departments, and better identify and address systems issues. Both private and public sector organizations can benefit from SCADA systems including small, basic manufacturing plants to large, multi-million dollar corporations.

Companies using SCADA systems include those in the following industries:

- Oil and gas

- Power

- Water

- Transportation

- Energy

- Food

- Healthcare

- Recycling

SCADA systems can be configured to do everything — from managing the operations of freezer and refrigeration systems at a food distribution company to reducing downtime on a production line at a manufacturing plant.

SCADA systems help businesses:

- Comply with health and safety regulations

- Meet government compliance requirements

- Boost efficiency; and

- Save money

The Origins and Evolution of SCADA

How SCADA Began

Before the technological age dawned, industrial organizations and manufacturing facilities employed teams of technicians to manually control and check on all their equipment to keep them operating. This highly resourceful and labor-intensive system used paper-based records, pushbuttons, and analog dials to perform monitoring and controls.

For smaller facilities, this manual system was workable for a time. However, as companies grew in size and reach, it became more difficult for them to rely on nonautomatic processes, especially over longer distances. Original automation tools began with timers and relays, which reduced the number of trips technicians needed to make to remote locations.

As growth continued, though, organizations found that timers and relays were not flexible enough and took up a great deal of physical space. Around 1950, computers were entering the picture and brought a new level of hope for industrial controls. One of the most useful initial developments was telemetry, which allowed off-site monitoring and data transmission.

SCADA originated in the 1970s with the advent of microprocessors and programmable logic controllers (PLC).

How SCADA Has Evolved

Like just about all industrial computer systems, SCADA was first implemented on huge, mainframe computers. This dictated the fact that they were standalone systems, functioning and housed in a single location. These were known as monolithic systems.

A couple of decades later, SCADA adapted to the shrinking computer hardware, PC-based software, and local area networks. This allowed the systems to break free of initial walls and join similar systems to share information and data more efficiently. However, many of these systems, known as distributed systems, were still proprietary and closed.

By the year 2000, SCADA joined the ranks of other computer systems in a more open environment. This now-networked SCADA system ran on ethernet, which allowed multiple systems, vendors, and partners to join the network and connect to the SCADA system.

Although technology has continued to advance, many industrial companies still use proprietary technology, making data transfer cumbersome. Some companies, however, have evolved to offer a SCADA system of linked and connected devices.

Historically, the challenge with SCADA systems was finding an efficient communication network to connect the devices. Early technologies relied on proprietary systems to link the components. Though effective to some extent, those systems had limitations in keeping up with the times.

Meanwhile, information technologies have been emerging over the last few decades. The development of structured query language (SQL) databases was significant in advancing data management. Modern SCADA systems incorporate SQL capabilities, further linking to enterprise resource planning systems for a smoother and more holistic operation.

Market research analysts also state that the industrial control systems market, which includes SCADA systems, is projected to reach $201.77 billion in 2025 and is expected to reach $309.03 billion by 2030. The Industrial Internet of Things, cloud technology, and evolving web technology will no doubt have an impact on future SCADA systems.

SCADA Benefits for Maintenance and Reliability Efforts

Since SCADA systems provide flexible, scalable means to monitor what’s happening throughout a complex production process, on a shop floor, or within remote substations, they can make a significant contribution to maintenance and reliability efforts.

Reliability-centered maintenance (RCM) is a maintenance strategy that boosts equipment and asset reliability to a top priority. The strategy is designed to optimize the maintenance system of an entire organization with the intent to improve efficiency and timely production. RCM typically focuses on identifying and prioritizing different failure modes. This focus helps in scheduling activities that will prevent major system failure.

It’s easy to see how SCADA can go hand in hand with an RCM system, as it provides a great deal of automated information and data on the performances of various assets and machinery in a plant. SCADA also allows human intervention early in the process, preventing the failures that an RCM strategy is designed to seek and identify. Here are some real-life applications.

Automating Electric Distribution

Electrical utilities around the world are facing an increase in the demand for power, as well as a lower-than-ever tolerance for outages. Maintaining these complex electrical grids and equipment to be as perfectly reliable as possible is a significant challenge. SCADA systems play an important role in helping utilities achieve that goal.

In this industry, sensors can collect information from various points at each substation. Additional manual data can be added by either the central or substation staff.

Besides collecting data and sending alerts when certain conditions signal an outage or potential for an outage, a well-programmed SCADA system can automate certain repairs. In addition, it can pinpoint the location of other problems, minimizing the time it takes for a technician to locate and diagnose the problem. Finally, various backup and redundant checks and processes can increase reliability throughout the power grid.

Identifying Failures on a Production Floor

Being able to identify potential failures before they occur is critical to maintaining a world-class level of uptime on any shop floor.

For example, let’s look at the failure of a steam turbine component. If the overspeed trip device is not working properly, it may have no immediate effect on your overall system.

However, a SCADA sensor that recognizes this failure is not designed to only repair that component. Instead, the sensor alerts the maintenance department of the issue so it can be repaired before its load drops suddenly and acceleration ensues. If the turbine is allowed to deteriorate to this level of failure, a company may incur damage from flying blades or even employee injury from the malfunction.

Manage Sensitivity and Security in IT

SCADA systems help IT and telecom organizations better control sensitive systems and monitor remote environments. Sensors can provide around-the-clock “eyes” on things like the temperature of servers or the humidity in rooms with sensitive IT equipment to avoid or minimize damage caused by environmental factors.

In addition, SCADA systems work well within security applications such as alarm contact closures, magnetic door sensors, and motion detectors.

Nerve Center of Alternative Energy

Wind-powered energy is rising in popularity as the world demands more renewable energy options. SCADA systems play a critical role in modern wind farms. The SCADA system brings each piece of turbine equipment together with substations and weather monitoring equipment.

SCADA systems can even track all activity on a wind farm within a 10-minute window, which gives the human operator near real-time activity tracking. If anything looks amiss in the system, action can be taken almost immediately to protect the equipment and safety of the surrounding community. In addition, the SCADA system can track energy output and any functionality errors that can be used as evidence for warranty claims on equipment.

Data is sent through a fiber-optic network that summarizes not only the performance of the turbines and other equipment but also the performance of the wind itself. Meteorological equipment must be incorporated into the system to determine if lower power production is due to equipment issues or low winds.

UpKeep: A CMMS System With Tools and Features To Maximize the Efforts of Your Maintenance and Reliability Team

SCADA systems, together with developments in IT technologies, are becoming an integral part of plant systems. They collect a wealth of data from key components and processes throughout an organization, regardless of geographical location. Technology then allows the transfer and conversion of that data into usable information. Human-machine interface systems display and deliver the data to skilled technicians who can make data-driven decisions quickly and efficiently.

SCADA systems can work together with RCM and maintenance strategies that focus on predictive maintenance. They provide the data and technology to allow a great deal of automation and data collection, which means that problems and failures can be spotted at a point before they cause major equipment damage, shut down an entire production line, cause a serious accident, or result in an environmental catastrophe.

When it comes to reliability and maintenance, you need a way to simplify, organize, and optimize your operations and team. UpKeep is a CMMS software solution that can do just that. Start boosting your company’s efficiency and production today. Get started with a 7-day free trial.

Want to keep reading?

Will Industrial Internet of Things (IIoT) replace SCADA?

What is the difference between PLC and SCADA?

Programmable Logic Controller (PLC)

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)