Run to failure maintenance is a maintenance strategy that is sometimes more appropriately called “Fit and Forget” because there is no maintenance plan beyond complete replacement upon failure.

It is an essential technique in certain aspects of industry. In essence, RTF tells you that no amount of maintenance will refill a toothpaste tube. When it’s empty, it’s at the end of its useful life. Buy a new one so it is ready to go when the other fails.

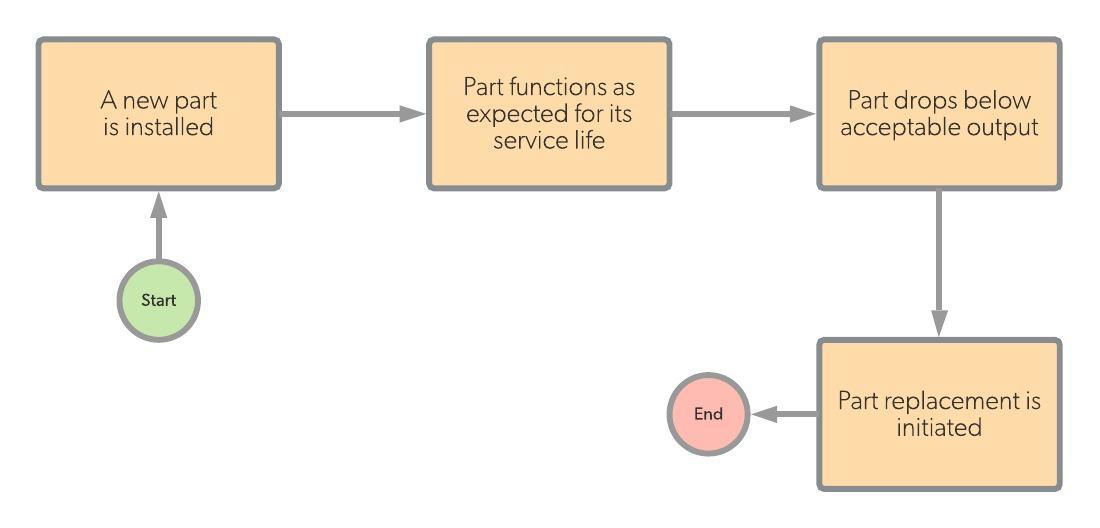

RTF workflow diagram

Overview

Run to failure maintenance should not be misconstrued as unintended failure replacement (UFR) which is failure from neglect or ignorance without a plan to cope. RTF is a very deliberate strategy where the item is intended to run until it fails and owners are prepared to take remedial action instantly upon failure.

In some industries, much equipment is RTF such as the space program where satellites are beyond human reach and simply cannot be serviced.

Where is run to failure maintenance applicable?

- Short life assets are not robust or particularly durable in design. Such would include incandescent light bulbs, overhead door motors, circuit pumps, water heaters, air-traffic warning lights on radio towers, or anything that is typically replaced 5 or more times in the lifetime of a building.

- Disposable assets are items which are generally inexpensive or single use. These could include car shock absorbers, automobile tires, signage, pneumatic pistons on assembly lines, most printer cartridges, all the way down to brooms and mops.

- Durable assets or non-maintainable assets are items that are not expected to wear out such as concrete foundations of buildings or the interior steel structure of a high rise building. They require no maintenance to fulfil their function and are not expected to fail.

- Low capitalization assets are those which might experience some maintenance, such as fire extinguishers being recharged after use, but are disposed of based on age or condition. It could include bike racks, office furniture, smoke detectors, fluorescent lamp ballasts, ceiling fans, exercise equipment, maintenance tools such as electric drills and tape measures, or office equipment like monitors, mice, keyboards, or chair mats.

- Non-critical assets such as a stove element failing would simply cause its likely replacement when it became inconvenient. Stoves typically have four or more surface elements so the functionality of the device is barely compromised with a single failure.

Run to failure maintenance requires good judgement

A dishwasher that is completely functional but makes squealing noises might be deemed to have failed if it were in the kitchen of an expensive restaurant and was disturbing diners. A failed part might be replaced, but in a commercial situation it could signal a string of upcoming repairs so the entire unit might simply be swapped out to expedite operations and save money.

Knowing when to declare wholesale failure as opposed to initiating repair is part of the skill set.

Benefits of run to failure maintenance

There are two beneficial outcomes while using RTF. One economizes on costs while the other enhances productivity. Ideally it is a mixture of both.

RTF can save money by eliminating the impact of regular maintenance. Inspecting and cleaning all of the sprinkler heads on a farm or golf course would have a huge time impact, driving up costs. It’s much simpler to note the occasional failure and replace the whole unit. The same could be said about drop ceiling tiles; any experiencing water or other damage are simply replaced since it is impractical to repair them.

To streamline and enhance operations to improve productivity, a facility with dozens of people assembling electronics will probably have replacement parts in bulk. Soldering irons, magnifying glasses, multimeters, and so on, are too inexpensive to maintain, and too labor intensive to service.

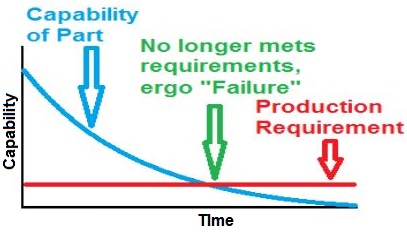

Graph of service cycle

Conclusion

At its worst, RTF is referred to as crisis maintenance because the status of equipment is unknown and the company faces unpredictable downtime when something breaks. Once implemented on appropriate assets, with intelligent planning for dealing with the inevitable failures, it saves time, saves money, and contributes to enhanced productivity.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)