Run to Failure vs Breakdown Maintenance

Run to failure (RTF) maintenance and breakdown maintenance both aim to fix problems that occur when equipment breaks down, although the intent of each maintenance plan looks slightly different.

In RTF maintenance, the maintenance team expects certain parts to break down and plans for that to occur, which is why this plan is often called a “fit and forget” plan. This means that no regular maintenance is performed on these parts because they will be replaced wholesale when they fail.

For example, a large facility will have a huge number of lightbulbs. In an RTF maintenance plan, the facility decides that it’s not economical to try and inspect every light bulb for proper functionality. Instead, they only replace light bulbs when they burn out, meaning they cut down on the maintenance cost of checking light bulbs, as well as the necessary number of spares kept on hand.

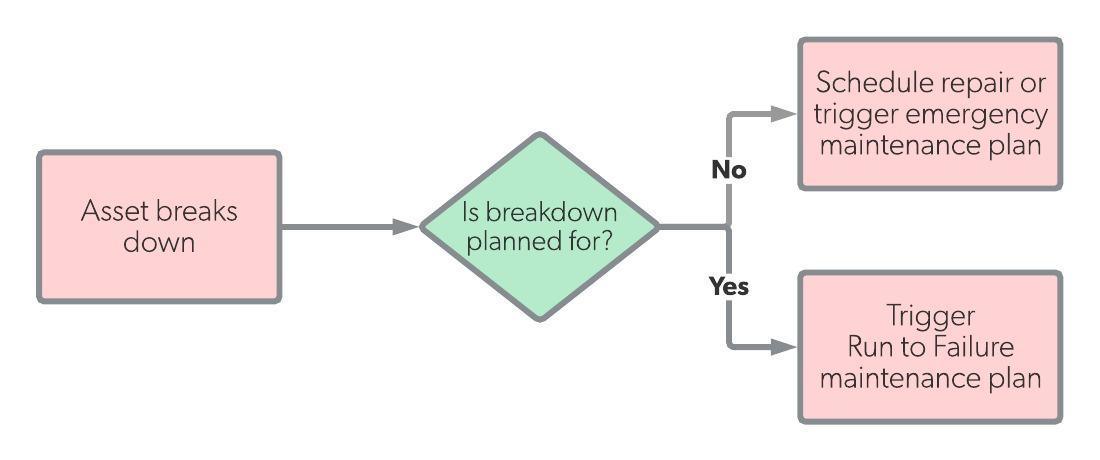

Breakdown maintenance is a far more general version of RTF maintenance. This is because RTF maintenance nests under breakdown maintenance. In fact, a run to failure plan is a kind of breakdown maintenance. However, this doesn’t mean that they are the same.

The umbrella of breakdown maintenance also includes emergency maintenance tasks or unplanned downtime events, making it a more versatile system. In a way, RTF maintenance is a “good” form of breakdown maintenance because it is planned, while unplanned downtime events (reactive maintenance) are the “bad” form of breakdown maintenance.

Because it is more general, breakdown maintenance has a place in almost every facility. Run to failure maintenance, however, requires some careful planning and knowledge, which makes it only useful for short life or disposable assets, durable pieces of equipment, or non-critical parts. Additionally, because RTF maintenance relies on parts breaking down, it cannot be used when the safety and health of people are involved.

Differences between run to failure and breakdown maintenance

| Run to failure maintenance | Breakdown maintenance | |

|---|---|---|

| Definition | Run to failure (RTF) maintenance is a plan wherein parts or equipment are run until they fail, at which point they are replaced entirely. | Breakdown maintenance (BM) refers to maintenance performed when equipment stops working, which can be planned (like RTF maintenance) or unplanned (like faults and unplanned downtime events). |

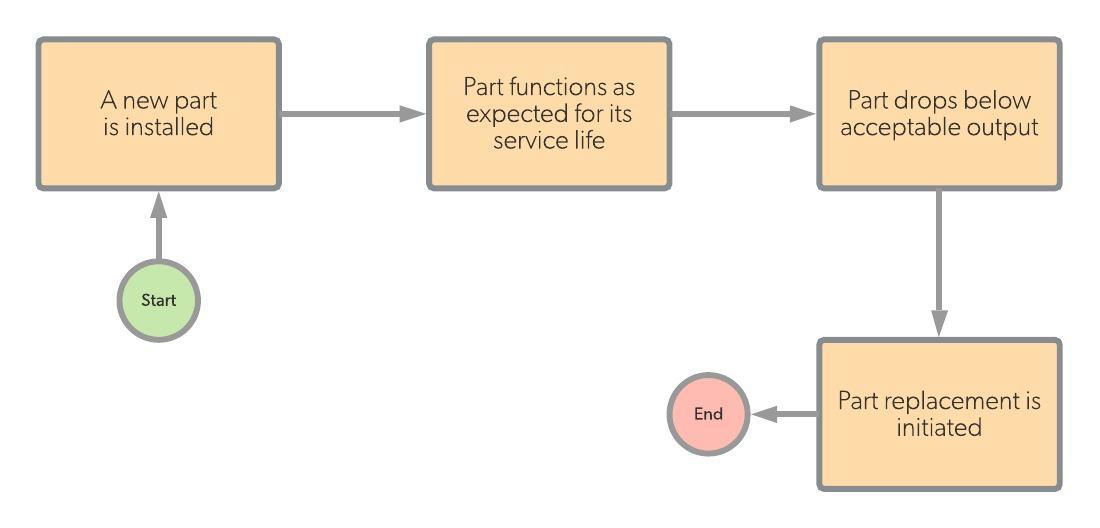

| Workflow |  |

|

| Trigger | Equipment breakdown | Equipment breakdown |

| Cost | Low | Low - High |

| Cost Savings | High (if implemented properly) | Planned breakdown can save money; unplanned breakdown maintenance can cost money, especially with critical equipment |

| Resources Needed |

|

|

| Pros |

|

|

| Cons |

|

|

| Use Case | A golf course realizes it’s too time intensive to do preventive maintenance on every single water sprinkler head on the course. Instead, they plan and implement an RTF maintenance plan, only replacing water sprinkler heads when the sprinkler head breaks or becomes unusable. This means the maintenance team has more time to perform other important work. | A facility requires two different components of breakdown maintenance: it needs a plan for any assets that are RTF parts (like light bulbs or soldering irons), as well as a plan for any unexpected downtime events. The implementation of this plan means that maintenance can utilize their time more efficiently, as well as providing a safety net for any unplanned machine breakages or faults. |

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)