UpKeep AI Suggestion

Search Results

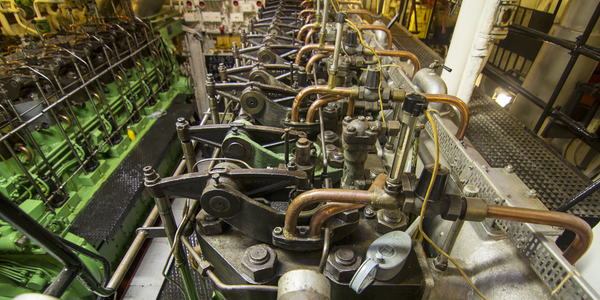

What are the different types of marine propulsion and how do you take care of machinery?

Want to keep reading?

How can preventive maintenance prevent an offshore oil spill?

Preventive maintenance ensures that equipment is in good working order. This may help prevent both small and large offshore spills in the future.

What is Routine Maintenance? | A Beginner's Guide

Routine maintenance is the regular inspection and servicing of machines and systems that keep operations running smoothly. Click to learn more.

Maintenance Optimization: Optimize Planned & Preventive Maint.

Planned Maintenance Optimization (PMO) is a method of improving maintenance strategies based on existing maintenance routines and failure history.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)

Many different types of propulsion options are available for boats including diesel, wind, gas and solar, and each type will require its own unique maintenance plan. Here’s a brief primer to help you get familiar with the basics.

Fuel Propulsion Options

Nearly a dozen different kids of propulsions involve a variety of fuels available today.

The most common is a diesel-based system that is frequently found in both smaller boats and larger recreational vessels. However, when early naval and other boating vessels were first created, most boats operated on steam turbine propulsion, water jet propulsion, and diesel-electric propulsion.

As environmental concerns have risen in recent years, other alternative forms of propulsion have evolved. For example, wind propulsion successfully powers merchant ships and solar propulsion, which can now generate power up to 40 kilowatts (kW). Biodiesel propulsion also shows much promise with testing in full force, and fuel cell propulsion is a very clean system that uses hydrogen for fuel.

Navel ships are experimenting with nuclear propulsion. Gas turbine options are one of the fastest propulsion systems, which are ideal for ships under attack, and tri-fuel propulsion allows a vessel to burn gas, diesel, or heavier fuels.

Propeller Options

Besides fuel types, technology that involves new propellers and add-on devices are now playing a significant role in marine propulsion. Besides conventional propellers that are either fixed or controllable pitch, new add-ons, podded systems, thrusters, and water jets are entering the power train of more and more vessels.

As boat owners, engineers, regulators, and marine-based companies consider the advantages and disadvantages of the intricacies of the developing marine power train, maintenance issues are sure to arise.

Routine Maintenance and Repairs

Marine engineers or specialty companies are responsible for ensuring that a ship is in good working order. Routine maintenance and repairs are critical to prevent major breakdowns or losses.

Routine maintenance for marine equipment is typically electrical or mechanical in nature. Equipment manuals specify when certain tasks must be completed, based on running hours. Life-saving equipment, spare part management, and emergency equipment must also be maintained. Marine engineers and mechanics typically work onboard large vessels to manage these tasks.For private boat owners, many of the routine maintenance tasks required on a boat are similar to caring for a car. Routine items, such as cleaning and lubricating, should be handled routinely by a boat owner. More complicated tasks involving HVAC, plumbing, and electrical systems should be left to the professionals.

Marine Maintenance Checklist

Here are some basic components you should include on your marine diesel maintenance checklist to keep your vessel functioning well.

One of the key components of marine maintenance is to ensure your vessel is well lubricated. Oil reduces the friction of a wide variety of moving parts, but it also helps keep the pistons and cylinders cool and seals out contaminants and corrosion. Simply change your boat’s oil and filters based on engine running time if you boat frequently or seasonally if you don’t.

Be sure to clean your sea strainers regularly, as they are the top cause of engine failure. The sea water works is a coolant to your engine’s fresh water system, so you want to be sure that this cycle is free from obstructions to keep your engine temperature low.

A few other tips include cleaning, if not replacing your impeller, each year. If you boat in freshwater, be sure that your pressure cap is secure and change your antifreeze every other year. Mixing elbows tend to get clogged over time and should be replaced every three years, and be sure to test your thermostat regularly.