What is Emergency Maintenance?

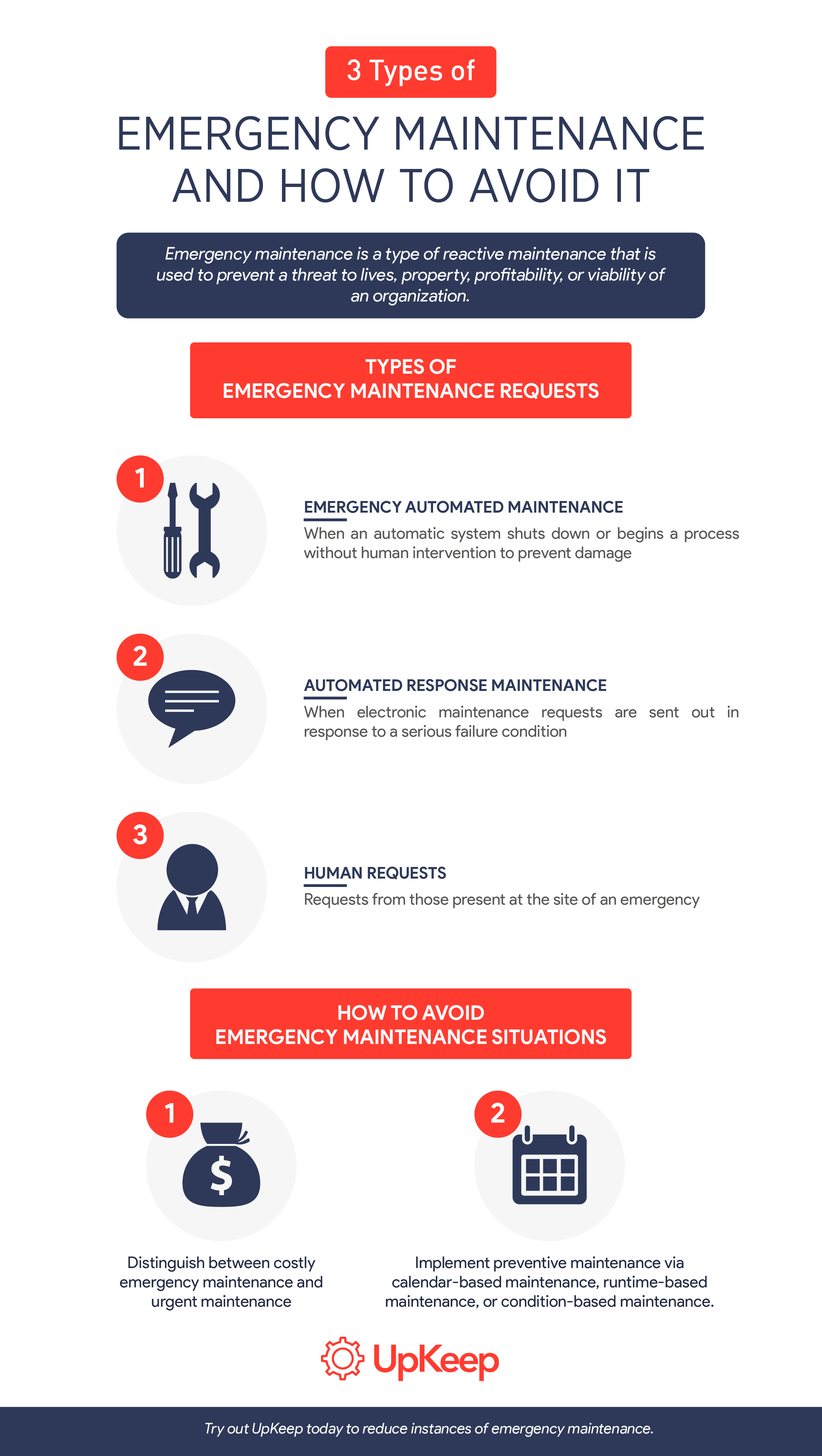

Emergency maintenance is a type of reactive maintenance that is used to prevent a threat to lives, property, profitability, or viability of an organization.

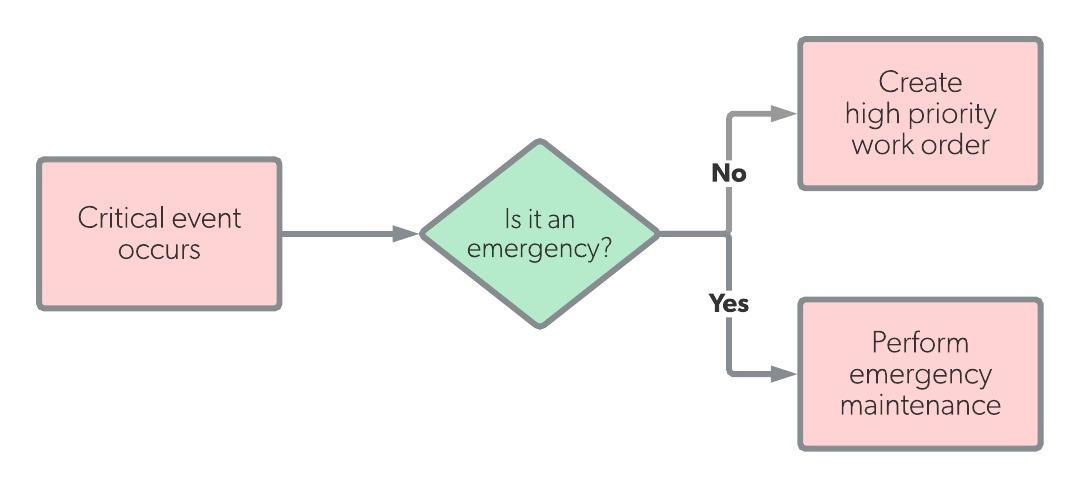

Emergency maintenance workflow

Overview

Whether in an industrial or residential setting, emergency maintenance (EM) is required when lives, property, or assets are under immediate threat. In a processing plant, for example, EM is applied to keep a facility safe and operational. In tenancy situations, EM protects the health and safety of residents as well as the building’s assets.

Having a properly prepared and executed preventive maintenance program will eliminate almost all emergency maintenance. Yes, a hydraulic hose on a tow-motor can still burst, or a windstorm can toss a tree branch through a window, but “The Inevitable” can be pushed far into the background when everything is generally in a good state.

Types of EM requests and responses

Emergency automated maintenance

This occurs when an automatic system shuts down or begins a process without human intervention to prevent damage, specifically when it places a call for help.

For instance, when a natural gas utility detects a sudden pressure drop in a gas delivery subcomponent, valves close to prevent uncontrolled escape. Similarly, an electric utility shuts down sections of the power grid to avoid a cascade failure of the entire system.

Automated response maintenance

This occurs when electronic maintenance requests are sent out in response to a serious failure condition, such as when elevators fail in a high-rise building or office tower.

Human requests

These are requests from those present at the site of an emergency and can spawn from shop floor personnel during system failures to tenants in the event of flooding or electrical failure. Events such as computer failure on a keyless-entry facility where keycard access to the building doesn’t work can warrant a human request for emergency maintenance as well.

How to avoid emergency maintenance situations

First, distinguish between costly emergency maintenance and urgent maintenance. Emergency maintenance needs immediate attention—even on a Sunday at double-time-and-a-half. Urgent maintenance can wait for normal business hours.

In a tenancy situation, if a toilet is clogged but the unit possesses another functioning toilet, it is urgent rather than an emergency. If an elevator is out of service and no one is trapped inside while other elevators remain functional, it is urgent rather than an emergency.

Making this distinction keeps costs under control. However, the best way to avoid emergency maintenance is to implement preventive maintenance. This can take the form of calendar-based maintenance, runtime-based maintenance, or condition-based maintenance.

The necessity for prompt emergency maintenance

Getting a facility back into full operation as quickly as possible is essential for the continued viability of a company, its profitability, and to enhance public perception of the company’s responsiveness.

When dealing with commercial facilities and residential properties, public confidence is an essential component of an organization’s income stream. And if the organization cannot provide a reliable service to customers, they will find alternatives.

According to a survey by Accenture, nearly half of 2,000+ people surveyed said poor service led them to change service providers in at least one industry.

Conclusion

EM can reach more than double the expense of a regularly implemented preventative program.

Take the Oroville Dam in Southern California for instance. Adequate preventive maintenance would have seen it ready for 2016’s winter weather. Instead, inadequate spillways required the evacuation of nearly 200,000 residents. Costs estimated at $275 million have now reached $1.1 billion—many times the annual maintenance budget for the entire project.

Even a reactive maintenance program is more cost efficient than emergency maintenance, though that does not significantly reduce the likelihood of EM becoming necessary. Any sort of regularly applied maintenance resists the death spiral of deferred maintenance where problems compound until they are impossible to manage.

![[Review Badge] GetApp CMMS 2022 (Dark)](https://www.datocms-assets.com/38028/1673900459-get-app-logo-dark.png?auto=compress&fm=webp&w=347)

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)