Download

Preventive Maintenance Guide: Core Principles and Implementation

The Preventive Maintenance Guide: Core Principles and Implementation provides a comprehensive overview of preventive maintenance (PM), explaining its key principles, such as regularity, tailored asset plans, and proper documentation. It offers actionable steps to develop effective maintenance schedules, optimize resource allocation, and track essential KPIs for evaluating the success of a PM program.

Unlock Your All Access Pass

The Preventive Maintenance Guide: Core Principles and Implementation is a valuable resource for any organization looking to enhance the reliability and efficiency of their equipment through proactive maintenance strategies. It delves into the core principles of preventive maintenance, such as regularity, consistency, and data-driven adjustments, ensuring that organizations can prevent costly breakdowns and maximize asset longevity. This guide also provides detailed steps for developing tailored maintenance schedules, optimizing resource allocation, and using a computerized maintenance management system (CMMS) to streamline workflows and automate tasks.

Downloading this guide offers immense value by equipping readers with the tools and knowledge needed to improve maintenance operations and drive better performance. From prioritizing critical assets to tracking essential key performance indicators (KPIs) like Mean Time Between Failures (MTBF) and Schedule Compliance, the guide empowers maintenance teams to make informed decisions that lead to reduced downtime, increased equipment uptime, and cost savings. It's an essential resource for anyone looking to elevate their preventive maintenance program and achieve operational excellence.

Want to keep reading?

Maintenance

The 2026 State of Maintenance Report

Maintenance

AI in Maintenance: How to Use It Today—and What’s Coming Next

Maintenance

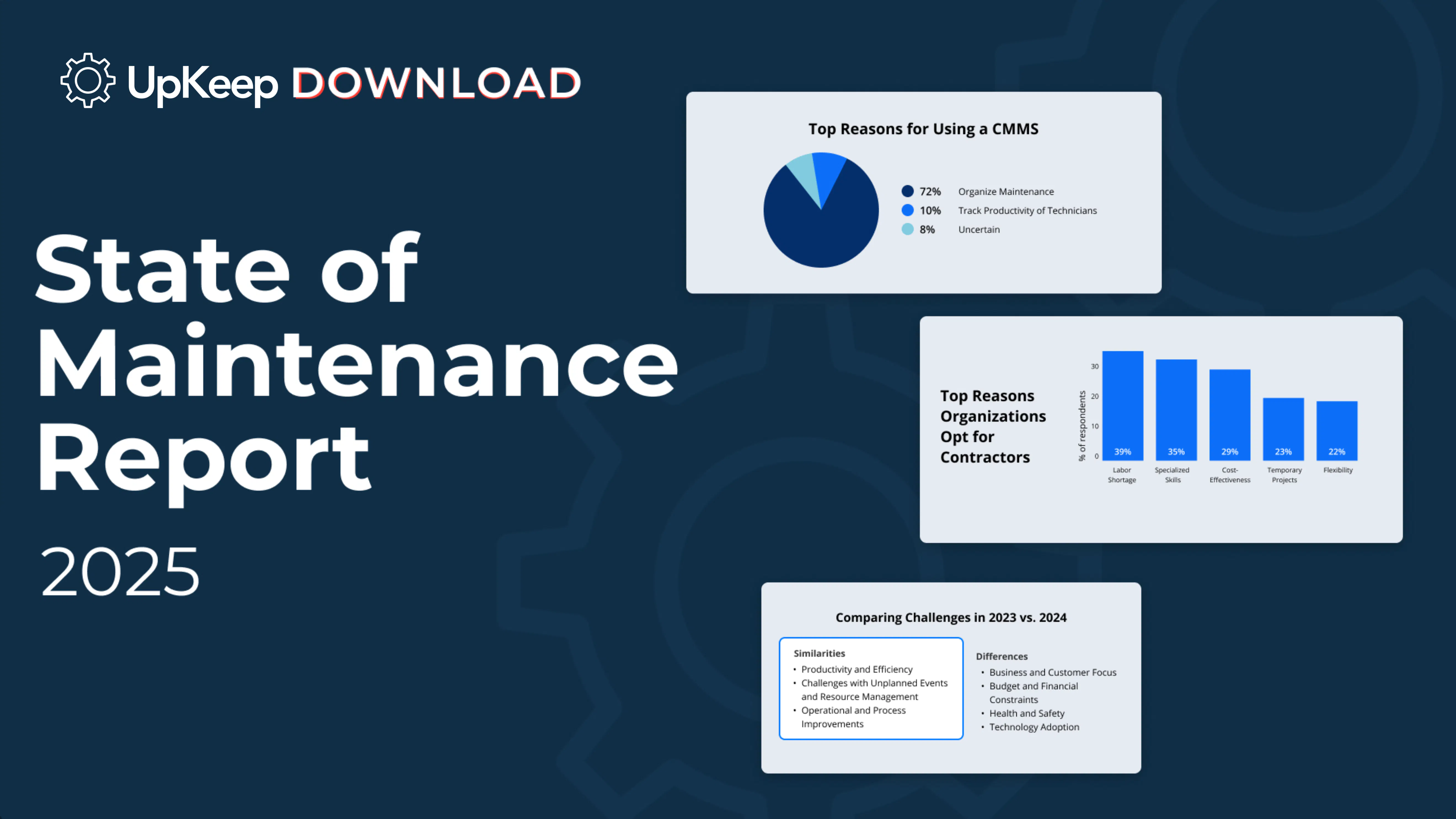

State of Maintenance Report 2025

4,000+ Companies Rely on UpKeep's Asset Operations Management Software