Downloads

Maintenance Maturity Model: Your Path to Achieving World-Class Maintenance Management

We've created the Maintenance Maturity Model to better help the community assess where they are. In this guide, we'll break down the overall Maintenance Maturity Model, as well as the required steps to move forward in the process, so you can achieve world-class maintenance management.

Unlock Your All Access Pass

Introduction

Something we’ve learned from working with over 3,000 customers and over 4,500 members of the maintenance community is that there are multiple stages an organization goes through on the journey to CMMS implementation and world-class maintenance.

A failed implementation is simply not an option for many companies. Thus, we’ve created this Maintenance Maturity Model to better help the community assess where they are. Through an overview and a more granular viewpoint, this guide outlines the typical journey a company goes through to become world-class. We’ve consulted industry experts and customers to create the Maintenance Maturity Model.

Unfortunately, many companies get stuck at level 1 or 2. This can happen for a variety of reasons, some of which include choosing the wrong technology, not getting team buy-in, and not aligning internally on objectives and the plan to get there. In this guide, we’ll break down the overall Maintenance Maturity Model, as well as the required steps to move forward in the process, so you can achieve world-class maintenance management.

How to Use This Guide

The Maintenance Maturity Overview sections look at the five stages of maintenance maturity that an organization goes through. Later in the guide, we tie the Maintenance Maturity Model back to the core aspects of CMMS: work orders and maintenance; asset management; inventory and procurement; and team, skills, and technology. The hope is that this guide will serve as a resource for you on your maintenance journey.

Maintenance Maturity Overview

Level 1 - Paper and Pencil

This is a team that still uses paper and pencil to track maintenance tasks. Generally, one person fields phone calls, writes the call notes on paper, and assigns work orders through another phone call or with paper jobs. Also, this team often uses spreadsheets to manage day-to-day scheduling.

Level 2 - Poor CMMS Implementation

This team has gone through a CMMS implementation, albeit a poor one. Only about half of what’s typical of a full CMMS implementation occurred. Some team members use the CMMS, but others don’t. In addition, the data isn’t consistent enough to be considered reliable.

Level 3 - Successful (Basic) CMMS Implementation

At this level, a team has achieved a successful basic implementation of a CMMS. Materials, parts, and assets are all logged within a CMMS most of the time; however, some data may be missing.

Level 4 - The Asset Manager

Here, a team has achieved a successful and complete CMMS implementation. The team has fully adopted the technology, and there is company-wide adoption with reliable data.

Level 5 - World-Class Maintenance

The success at this level is no longer just about the number of work orders completed but also managing and maintaining the uptime of equipment.

Work Order Management

Excelling in one area but not the other? Use the following sections to examine what's needed to get to the next step.

Paper and Pencil

This team’s work orders are primarily reactive. Scheduling is done in a spreadsheet, and work history is kept in a filing cabinet.

Poor CMMS Implementation

A majority of this team’s maintenance is reactive, with only some performed on a preventive and time-based maintenance schedule. In this level, maintenance technicians take phone calls from the team, enter information into the CMMS, and assign work through a digital system.

Successful (Basic) CMMS Implementation

Most of this team’s work orders are performed on a time-based or condition-based maintenance schedule. More than 50% of their jobs are preventive, more than 80% are planned, and less than 20% are reactive.

The Asset Manager

95% of the team’s work orders are planned, and less than 5% of the work orders are reactive. Also, automation is set up to alert stakeholders when certain triggers are hit, and workflows are defined for specific priority levels.

World-Class Maintenance

Nearly all work orders are kitted with correct parts and are planned/scheduled ahead of time. This team also has a formal strategy around preventive maintenance optimization, where a dedicated person is constantly evaluating the effectiveness of preventive maintenance schedules.

Asset Management

Paper and Pencil

The team has no clear asset repository; however, they may have records stored in filing cabinets. Some of these records include warranties and purchases.

Poor CMMS Implementation

For 75%+ of their critical assets, this team has simple asset records such as a name, model, type, and location. The team generally doesn’t have asset hierarchies, components, or a bill of materials on their assets.

Successful (Basic) CMMS Implementation

All assets are logged into the digital system, but it may not include information like warranties, cost, or depreciation of the assets. Most, if not all, of the assets have a full bill of materials. In addition, there’s a good asset hierarchy structure. And finally, teams may log downtime and track overall equipment effectiveness, but it might not be done on a consistent basis.

The Asset Manager

Technicians make repair vs. replace decisions based on warranty, depreciation schedules, current asset values, and purchase price. Each asset has a dedicated owner as well. Also, all major assets have their full manufacturers guide included, and there’s a clear history of who’s done what and when. Finally, the team follows ISO asset management standards and asset hierarchies such as ISO 14224.

World-Class Maintenance

The organization’s asset management is measured by overall equipment effectiveness and the reduction in downtime, instead of just knowing who’s done what. This team has also integrated sensors and hardware that triggers uptime and downtime reports. They have analyzed failure modes and have defined all of the different failure codes for critical assets.

Inventory and Procurement

Paper and Pencil

There is no clear owner of a storeroom or the inventory. The company may have an inventory, but it’s not managed by anyone and is generally used as a storage closet more than an inventory room. Often, people just pick up their parts and inventory from a local shop.

Poor CMMS Implementation

Some, or most, of this team’s parts are logged in the system; however, the parts and inventory don’t match the actual storeroom on a regular basis. Additionally, there’s no clear schedule for storeroom cycle counts and responsibilities.

Successful (Basic) CMMS Implementation

Most, or all, of their critical parts are included in the CMMS. It includes everything from quantity and cost to purchase price and date.

The Asset Manager

Inventory levels are correct 100% of the time. Also, team members can rely on the digital inventory as a direct reflection of what’s in their storeroom. Typically, this team has done failure analyses, and they understand which parts are critical as backups to have on hand.

World-Class Maintenance

At this level, parts are forecasted by the procurement department more than six months ahead of schedule. The team has also set up workflows to repurchase parts and inventory.

Team, Skills, and Technology

Paper and Pencil

Technicians generally don’t have advanced training in their craft. These workers are also lower-wage technicians that service almost as a handyman versus a specialized mechanic or vibration analysis technician. This team is often still using paper and pencil as well.

Poor CMMS Implementation

This team has moved to a digital system where maintenance records are stored, but that’s the extent of their efforts.

Successful (Basic) CMMS Implementation

This team is actively using, and accountable for, a CMMS to log the work that they’re doing.

The Asset Manager

At this point, you have a successful CMMS implementation and light integrations set up with different systems. The team is also split into specialized craft technicians. For example, the team might have a vibration analysis technician, fluid analysis technician, mechanic, or welder. This team has taken advanced training as well and has an intermediate to advanced competency level.

World-Class Maintenance

A root cause analysis is conducted when breakdowns occur, and there’s a formal investigation process to better understand root causes. Technology is deeply integrated with other systems. For instance, maintenance workflows are triggered by SCADA/PLC systems on machines. Finally, there’s a formal strategy around reliability-centered maintenance or total productive maintenance.

Want to keep reading?

Maintenance

Guide to Maintenance & Reliability Work Management

Maintenance

Cultivating Maintenance Excellence: The Role of Culture and Leadership in Reliability

Maintenance

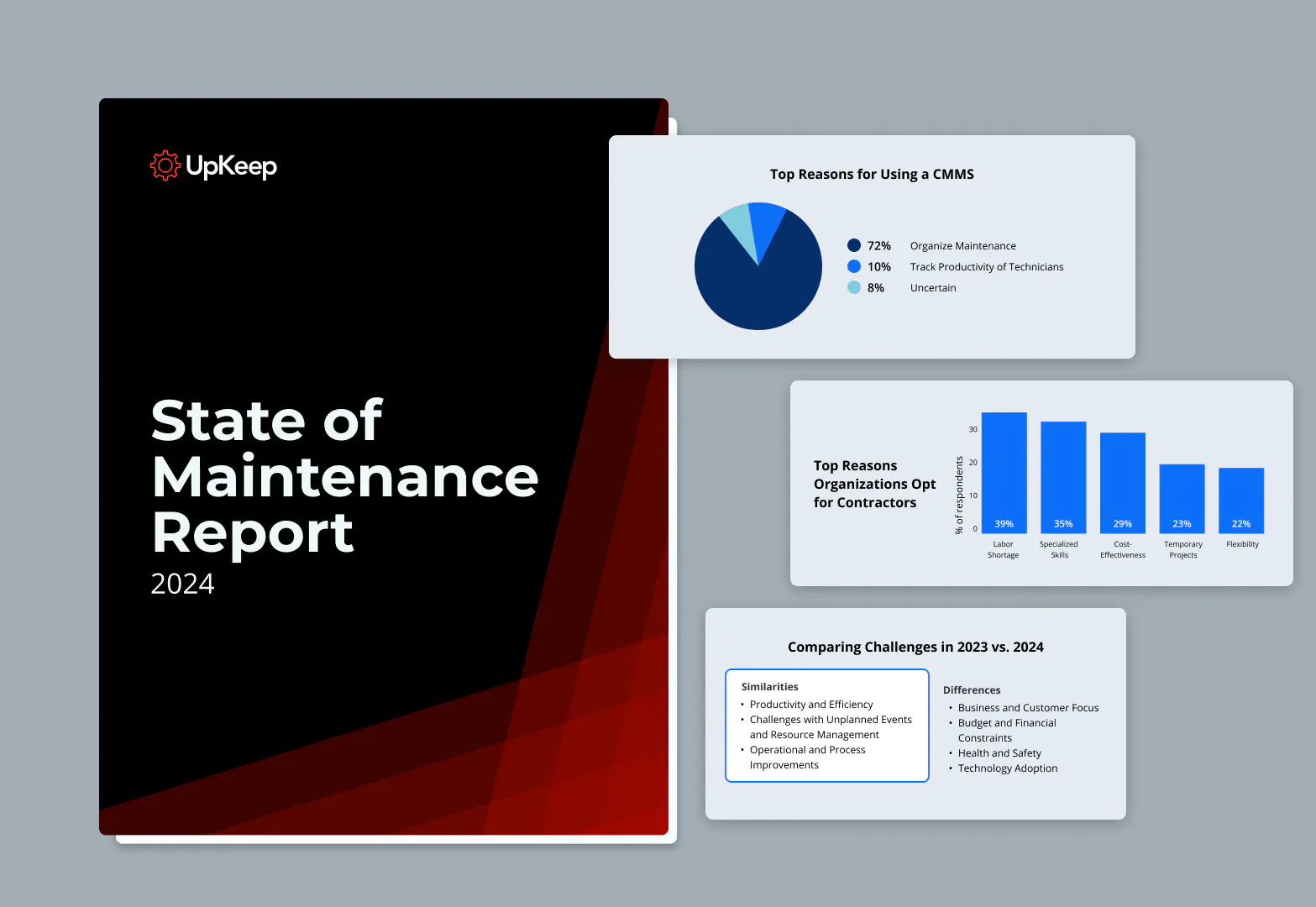

State of Maintenance Report 2024

4,000+ Companies Rely on UpKeep's Asset Operations Management Software