Download

Guide to Maintenance and Reliability Materials, Parts, and Inventory Management

This guide provides comprehensive strategies for the effective management of maintenance materials, parts, and inventory. It covers essential topics such as storeroom operations, inventory categorization and tracking, optimization techniques, and layout solutions, all aimed at enhancing equipment reliability, minimizing downtime, and optimizing costs.

Unlock Your All Access Pass

Download this guide for in-depth insights into the management of maintenance materials, parts, and inventory, emphasizing best practices for ensuring operational efficiency. It explores key areas including the organization and categorization of inventory, implementation of security measures, and integration of advanced tracking systems. By adhering to the principles outlined in this guide, facilities can achieve streamlined storeroom operations, accurate inventory records, and effective control over access and usage of parts.

Additionally, the guide delves into optimization techniques such as Economic Order Quantity (EOQ), ABC analysis, and Just-In-Time (JIT) inventory management. It provides practical advice on maintaining optimal stock levels for critical and non-critical spares, managing obsolete inventory, and leveraging technology for enhanced inventory accuracy. With detailed strategies for effective storeroom layout, environmental control, and ergonomic storage solutions, this guide equips organizations with the tools needed to minimize downtime, reduce costs, and ensure the availability of essential parts and materials.

Want to keep reading?

Maintenance

The 2026 State of Maintenance Report

Maintenance

AI in Maintenance: How to Use It Today—and What’s Coming Next

Maintenance

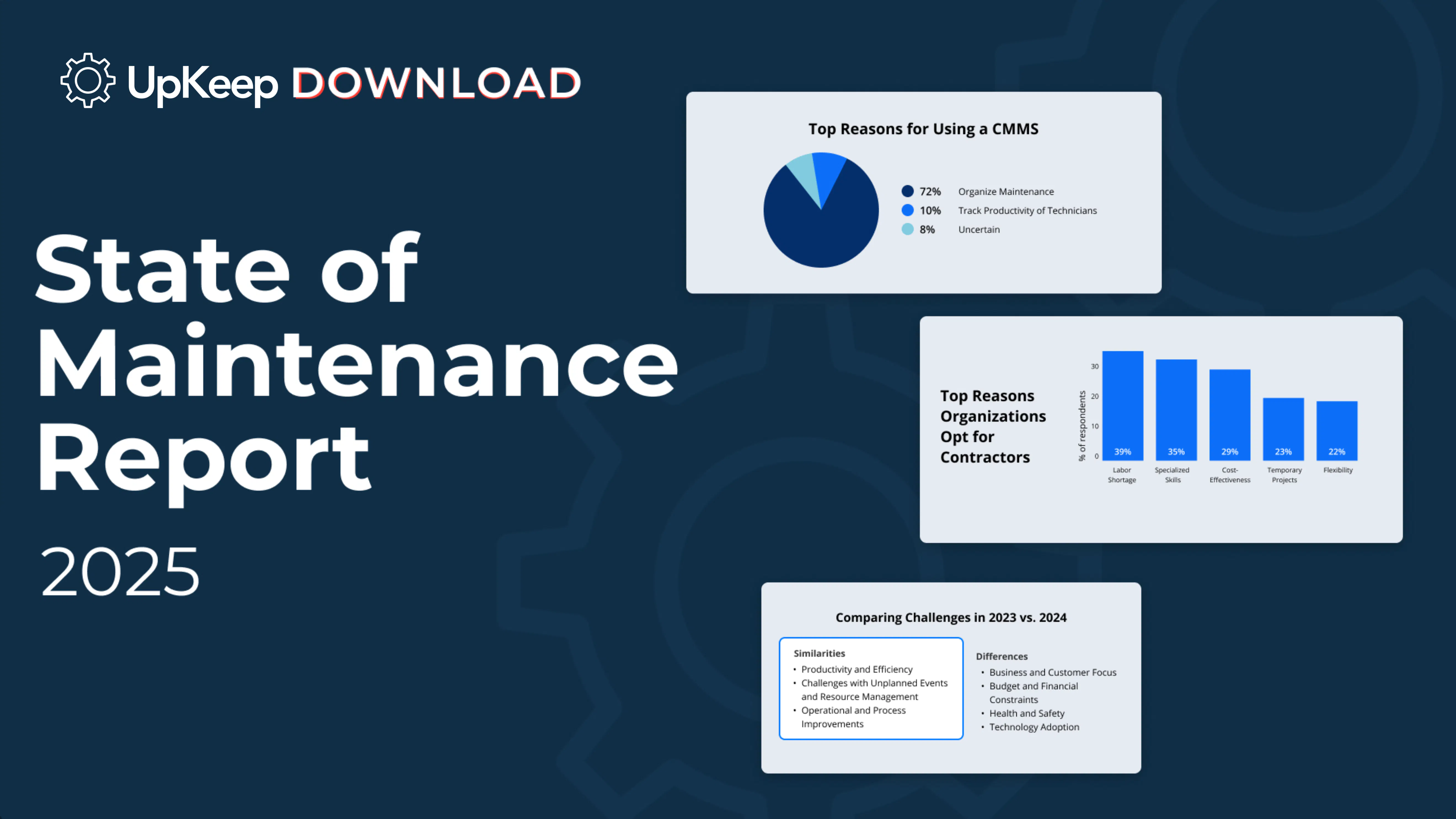

State of Maintenance Report 2025

4,000+ Companies Rely on UpKeep's Asset Operations Management Software