Blog Post

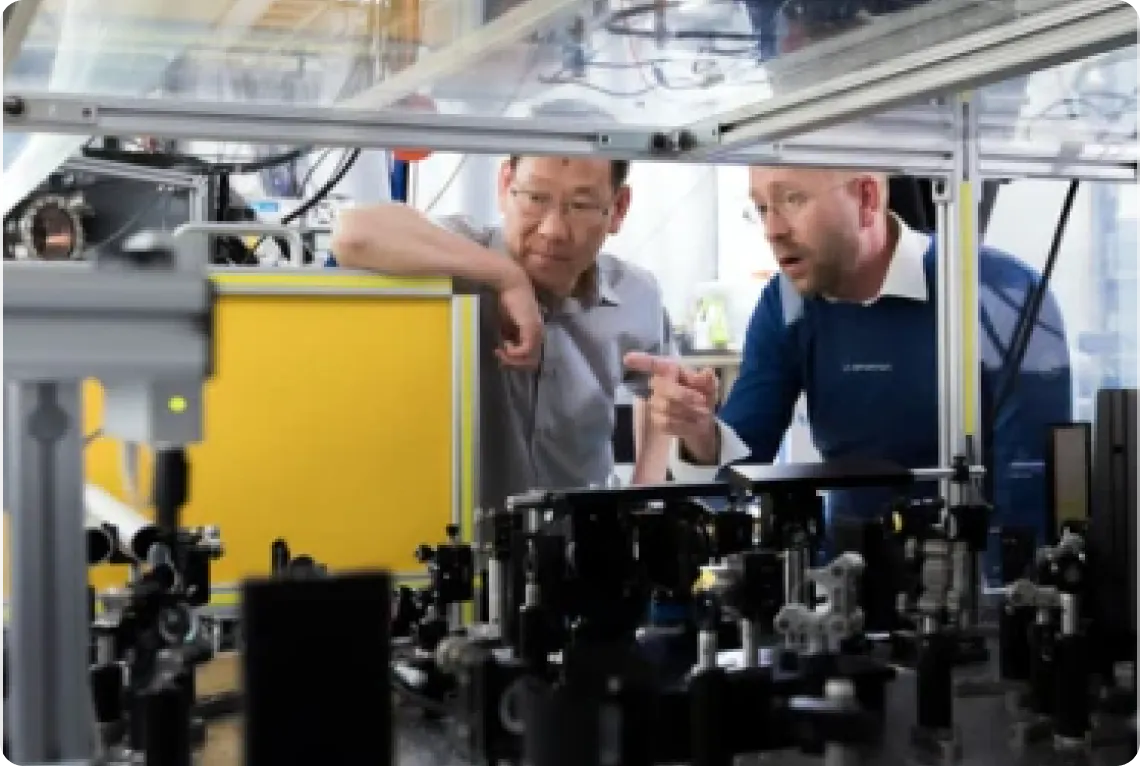

Using Sensors in Condition-Based Maintenance: Enhancing Equipment Reliability

Condition-Based Maintenance (CBM) leverages real-time monitoring to detect early signs of equipment failure, and sensors play a pivotal role in this process. By integrating sensor technology into maintenance strategies, businesses can make data-driven decisions that optimize performance and minimize unexpected failures.

Want to keep reading?

Article

How to Integrate Preventive and Condition-Based Maintenance into Reliability-Centered Maintenance Methodology

Article

Predictive Maintenance Sensors: Benefits and Cautions

Article

Which Sensors Are Best for My Industry?

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)