AOM Platform

The Asset Operations Management Platform

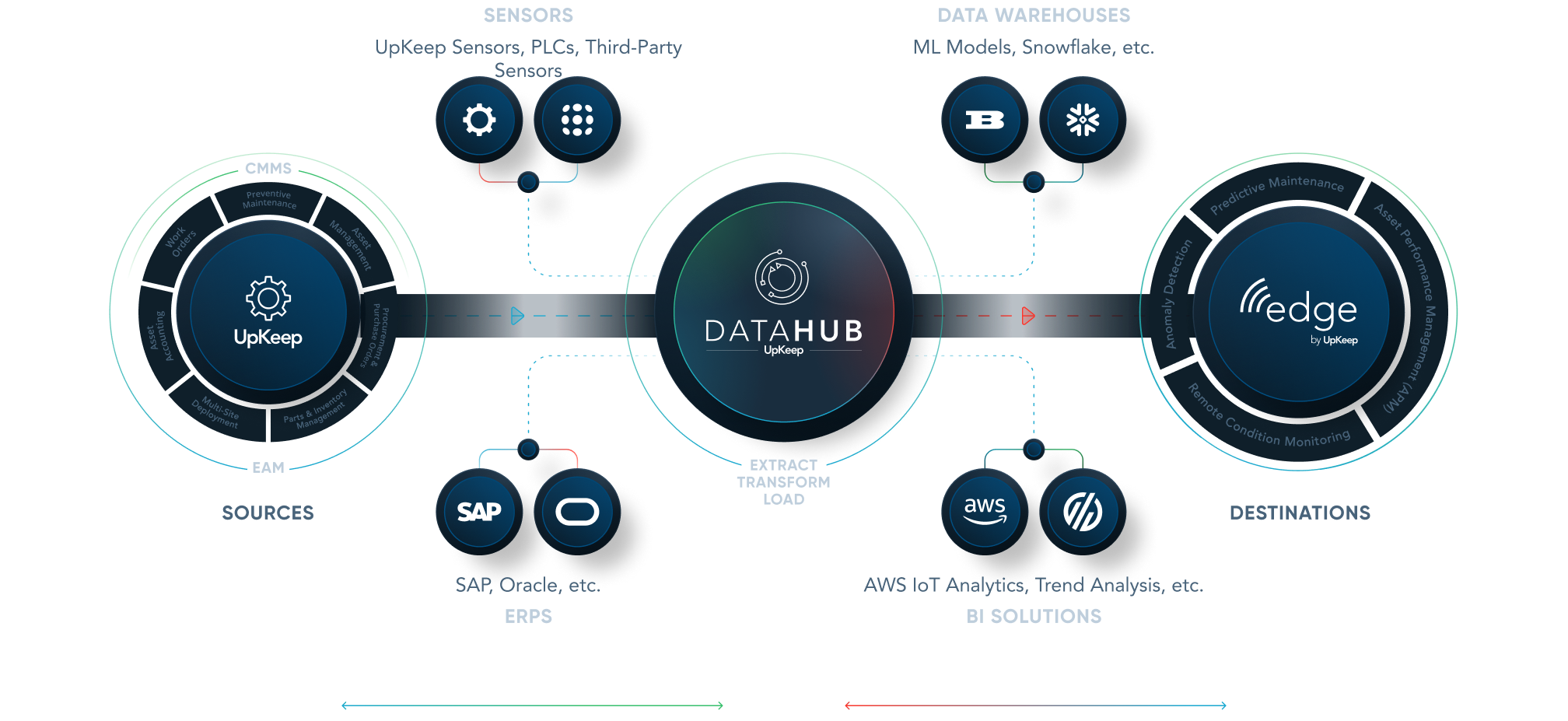

Asset Operations Management unites maintenance, operations, and reliability data to help teams make important business decisions, with full visibility across the entire life cycle of maintenance, asset management, and operations.

It’s the best of a CMMS, EAM, and APM solution all-in-one.

Get a Free Product Tour

The Platform

The UpKeep Asset Operations Platform

Asset Operations provides real-time data into the day-to-day maintenance life cycle, asset utilization, and performance measurement to support informed decisions that optimize maintenance strategies, improve asset performance, and increase availability and reliability. Our customer success team has the best asset operations process, our community enables you to train your people, and we make the best technology to accelerate all of this.

UpKeep Capabilities for Maintenance Teams

Asset Operations Management (AOM) closes the divide between maintenance, reliability, and operations teams by fusing capabilities found in CMMS, EAM, and APM solutions. This captures and leverages active and passive data from each functional area to provide a complete asset operations life cycle view.

Our solution is mobile-first and designed for ease of use in the field and office, with an emphasis on painless adoption throughout your organization to help create a single source of record. What does that mean for your maintenance team?

Increased team efficiency and equipment reliability

Access to comprehensive reporting and analytics to gain new insights

A solution that’s mobile-first, easy to use, and loved by technicians

UpKeep Capabilities for Operations Teams

Operations teams can use Asset Operations Management to get a holistic view of their company’s programs while also linking team-specific metrics to the broader business goals. Asset, maintenance, and reliability data can now be linked to executive metrics like revenue, cash conservation, margin, and more. Furthermore, Asset Operations Management provides:

One operational blueprint for efficient operations

Reporting and analytics to inform company strategy

Faster response time

The tools for teams to be seen as a business drivers as opposed to a cost center

UpKeep Capabilities for Reliability Teams

With Asset Operations Management, reliability teams can get the data they need to inform their programs and strategies. This new paradigm is supported by easy-to-use, affordable technology that offers the same advanced capabilities as enterprise-grade solutions without the sticker shock. By offering sophisticated functionality, including sensor-based asset monitoring, Asset Operations Management helps reliability teams adopt predictive maintenance practices in a cost-effective and scalable manner:

24/7 condition-based monitoring of assets

Easier work management for teams of all sizes

Precise, consistent documentation for audits

The ability to be prepared for whatever happens next

90%

Reduction in technician time spent filing work orders and locating asset information

315%

Return on Investment

$638K

Savings from avoided production downtime

Source: Study conducted through a third party through Forrester. Download the full report here.

Asset Operations Management Capabilities

This mobile-first solution centralizes data from across teams and devices into one, configurable, and easy-to-implement solution. Asset Operations Management provides real-time data into the day-to-day maintenance life cycle, asset utilization, and performance measurement to support informed decisions that optimize maintenance strategies, improve asset performance, and increase availability and reliability. Learn more about our solutions to find the best fit for your team.

CMMS Capabilities

Organize, monitor, and manage asset maintenance in your facility or plant.

EAM Capabilities

Analyze and optimize asset management data and intelligence that spans the asset life cycle.

APM Capabilities

Combine asset, maintenance, and reliability data to monitor and optimize asset maintenance planning.

One Centralized Command Center for Maintenance and Reliability Teams

Bring cost and revenue to the forefront under one umbrella to look past WHAT teams are doing to the impact they are making. In this Forrester Wave™ report featuring UpKeep, a manufacturing company was able to achieve incredible results, including:

90% Reduction in technician time spent filing work orders and locating asset information $638K Savings from avoided production downtime

Additional Resources

On-Demand Webinar

Maintenance & Reliability 2022: From Cost to Revenue Driver

Learn how maintenance, operations and reliability professionals can leverage technology to chart a new course and earn a seat at the revenue table.

Book

We Wrote the Book on Asset Operations!

UpKeep brought maintenance, reliability, and operations teams together in a new approach called Asset Operations Management. Now, we’ve written the book! We’re thrilled to announce the publication of Asset Operations: The Future of Maintenance, Reliability, and Operations.

Buyer's Guide

IDC: The Definitive Buyer's Guide for Asset Operations Management Applications

Use this guide to help navigate asset operations management software selection to capitalize on digital-first efficiency gains where data and workflows are automated and connected.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)