Success Story

Addison-HVAC Works Offline Effortlessly with UpKeep Mobile

Since UpKeep released our new offline mobile capabilities, Addison-HVAC’s maintenance technicians have enjoyed a seamless process of maintenance work while transitioning between online and offline situations. The new capabilities have enabled continuous work, an improved knowledge base, and higher morale across the team.

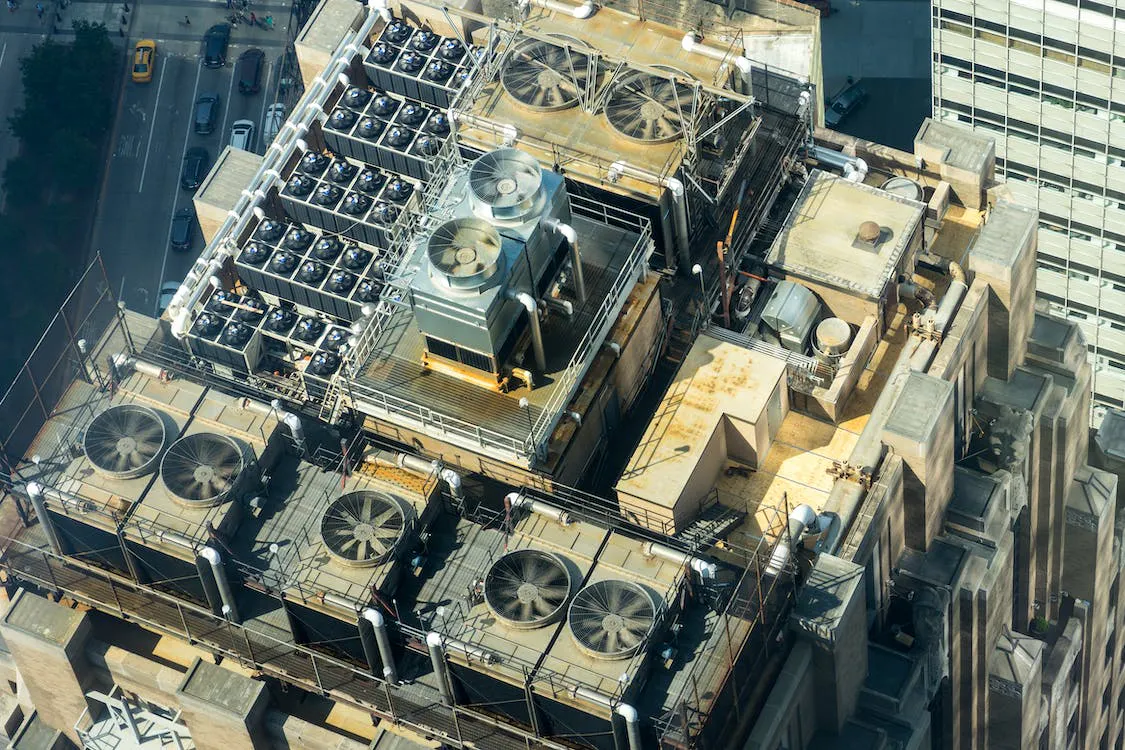

Addison-HVAC is a well-established DOAS (dedicated outdoor air system) manufacturer based in Orlando, Florida. They specialize in HVAC cooling and dehumidification equipment for commercial and industrial applications while offering a variety of energy-efficient options. We had the opportunity to sit down with their Maintenance Coordinator, Antwain Henry, to learn about their initial transition to UpKeep and, today, how their Technicians benefit from the offline mobile mode.

Challenge

Addison-HVAC employs a team of five technicians, including a maintenance supervisor. Before Antwain implemented UpKeep, the team used a physical paper request box and an Excel spreadsheet for managing maintenance activities. Aside from the manual aspect of filling out, reading, recording, and then communicating requests - the team often had grease on their hands from working, which made paper processes literally that much messier!

Additionally, the Addison-HVAC team has limited Wi-Fi or internet access about 70% of the time. Inside, the coverage is simply spotty, and, at times, Antwain’s work is out in the woods of Florida, on the roof, etc., and sometimes the wifi coverage just isn’t available.

Solution

Implementing UpKeep has transformed Addison-HVAC into a modern maintenance team, with easily created digital work orders that can be systematically reviewed, assigned, and completed.

With the new offline mobile capabilities, Antwain’s team has a seamless transition between offline and online situations, so they don’t even realize they’re offline. Everything they need offline is automatically available, like pictures and checklists, and their work orders automatically sync once a wifi connection is re-established.

Training was not even necessary as the solution “just works.”

Results

Before the new offline mobile capabilities, Antwain would try to remember details while he was troubleshooting, but those details rarely made it back into the knowledge base. It was just too cumbersome to investigate and work, and then need to come back and take notes. Now Antwain and his team can perform their maintenance activities, capture information in real-time, and effortlessly sync that information without any additional steps from the end-user.

Moreover, adoption has improved with the offline mobile capabilities because the Technicians can continue working without interruption or needing to go back and fill out notes after the work is completed.

What's Next?

Antwain is excited to explore the out-of-the-box reporting and analytics provided by UpKeep and take the next step of helping his team transition to predictive maintenance. He’s also excited about the continued innovation that UpKeep provides and is looking forward to mobile supporting video for an even deeper understanding of maintenance situations.

Want to keep reading?

Equipment / Manufacturing

Alto Products moves from reactive to preventive maintenance

Equipment / Manufacturing

Innovative Micro Technology creates a safety-focused culture

Equipment / Manufacturing

Columbia Fruit saves money with organized inventory

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)