Facility Maintenance Software: Make Facility Maintenance Requests Front and Center

With UpKeep’s facility management software, your maintenance team can plan for today, tomorrow, and beyond with agility and confidence.

No credit card required.

25-40%

Safety Event Reduction - Drop in injuries, claims, and downtime through proactive safety management

75%

Faster Response Time - Improvement via mobile alerts, automation, and streamlined workflows

300-500%

Overall ROI - From injury prevention, admin savings, and process automation

Achieve Your Best Response Times To Maintenance Requests With Facility Management Software

Increase transparency and visibility into work orders

Managers can utilize our facility maintenance software to create and approve work orders on their smartphones. Implementing preventive maintenance through a mobile device with updates, alerts, and notes ensures team accountability.

Reduce response times for work order completion

Technicians receive push notifications on their smartphones when a work order is assigned to them. Managers can mark the priority level to delegate repairs seamlessly from anywhere.

Streamline maintenance requests in one place

Give anyone the unlimited ability to submit and track work requests from a mobile device, desktop on a company-specific online portal, or from their email. Requesters are notified of any status updates, so they are always in the loop.

Reduce equipment downtime with preventive maintenance

Reduce maintenance costs and maximize uptime with routine inspections and checklists with our software for facilities management. Keep track of important checks to comply with OSHA audits and ensure your organization follows the highest safety standards.

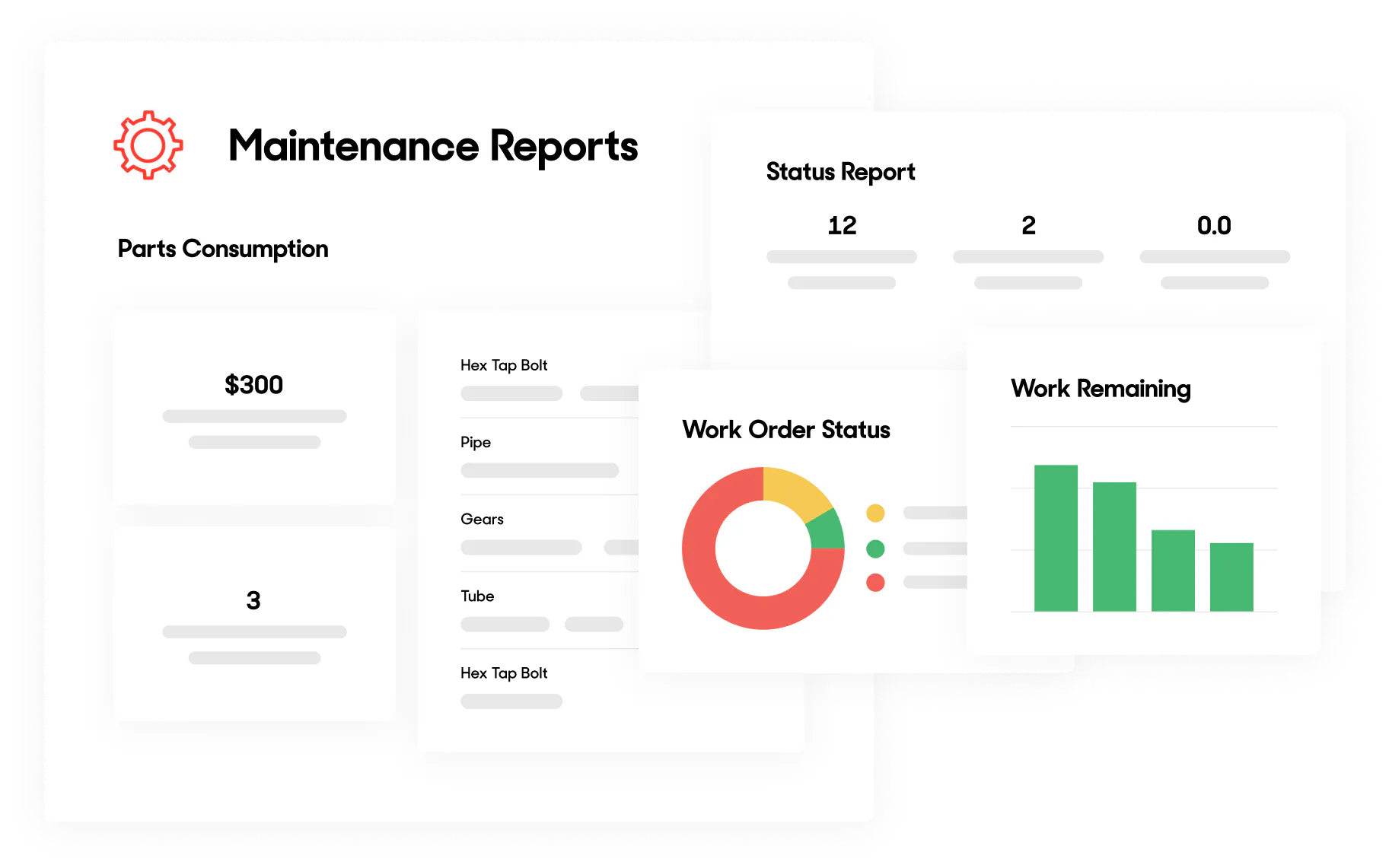

Easily run beautiful reports and data visualizations

With UpKeep Analytics, you can monitor the health of your assets over time and see how many work orders your team has completed, labor trends, costs, and more.

Provide clear documentation of inspections

Add inspection tasks to your checklists and work orders. Automate failed inspections to trigger follow-up work orders. Record meter readings, temperature, and more all within our building maintenance software.

Explore Case Studies

Explore more case studiesWhy Is Facility Management Important and How Can Facility Maintenance Software Help?

When done poorly, facility maintenance becomes noticeably important. Uncomfortably cold conference rooms, unkempt restrooms, broken machinery, or safety hazards stand out to all those trying to work in a particular building.

Facility management is important because it keeps all aspects of a building running smoothly and efficiently, supporting the environment that helps employees stay productive and safe.

Done well, facility management can also reduce overall energy costs and optimize maintenance resources.

Here are some industry facts that illustrate the importance of facility management and facility maintenance software. It helps to:

Use Space Effectively. Because real estate is one of the top costs for any business, using space effectively through good facility management can help an organization save upwards of 30 percent.

Manage Capital Projects. Most capital projects go over budget by 80 percent and may run nearly two years behind. Facility management efforts that incorporate project management technology can help reduce those costs and tighten the timeline.

Reduce Wasted Employee Time. In this country alone, employees spend more than 160 million days each year looking for conference rooms, offices, desks and equipment, and fellow teammates. Facility management can help manage and communicate the location of people and items more effectively.

Decrease Turnover. Although a work environment may not immediately come to mind in examining turnover, a comfortable and safe building means higher employee engagement. This, in turn, reduces turnover by nearly 60 percent as well as absenteeism by 41 percent while boosting productivity by 17 percent.

Increase Building Efficiency. Smart building technology that’s integrated can help organizations boost efficiencies of up to 50 percent.

What Are the Benefits of Good Facility Management?

When a facility is managed well, things run smoothly for all those working and using the building. Here are a few tangible benefits an organization may experience when using facility maintenance software:

Cost Reduction. If facility management is done proactively, an organization can easily reduce emergency repairs, which can be very expensive compared with preventive tasks.

Safer Environment. When repairs are made in a timely way, the work environment can be safer for all employees. This can encompass basic fire safety and alarm systems as well as ensuring faulty machinery is repaired before it becomes dangerous.

Efficiency Improvement. Ideally, all assets are working at optimal levels at all times, helping to keep employees productive and equipment functioning well. Facility maintenance software can help support that goal.

Regulatory Compliance. In some industries, complying with governmental regulations is critical to staying in business. A strong facility management program can ensure an organization has records to easily pass inspections and audits.

Productive Employees. Everything from a comfortable work environment to operating machines can add to the productivity of operators, employees, and technicians. Facility maintenance software can ensure both the tools and the environment support a positive workplace.

Longer Asset Lifespan. By taking care of critical assets, an organization can often extend its life cycle significantly, reducing the need to replace an expensive machine as well as all the costs associated with replacement.

Customer Satisfaction. Along with productivity comes meeting customer expectations. If production lines are working at optimal speeds, it’s more likely that a business can meet or exceed customer expectations, resulting in fewer complaints, more customer loyalty, and higher profits in the long run.

UpKeep’s Experts Here To Help You: Incomparable Training, Implementation, and Support To Ensure Your Success

The UpKeep Customer Success Team works like an extension of your team, helping customers hit their maintenance goals by providing useful, reliable customer support, a help center, and a personalized plan to help you grow with UpKeep.

Support

Help Center

With our facility maintenance software, you can schedule and respond to anything that needs repair or replacement, such as utilities, plumbing, door security, and more.

24/7

Customer Support

Keeping everything up and running is an enormous task. Save yourself time and money by automating the entire process with software for facilities management by UpKeep.

Book

We Wrote the Book on Asset Operations!

UpKeep brought maintenance, reliability, and operations teams together in a new approach called Asset Operations Management. Now, we’ve written the book! We’re thrilled to announce the publication of Asset Operations: The Future of Maintenance, Reliability, and Operations.

Streamline Facility Management On-the-Go: Mobile Features for Facility Maintenance Software

Centralize All of Your Work Requests with a Mobile Facility Maintenance Solution

Never waste time looking for a work request. Unlimited free requesters in our facility maintenance software can submit work requests and track the status of their requests.

Technicians can easily track all time spent on tasks using a timer. Reliable data collected directly from technicians' smartphones helps managers plan realistic PM schedules.

Reduce interruptions and accomplish more work with software for facility maintenance. Replace radio chatter and phone calls with comments and updates on the status of work orders.

CMMS, Maintenance Managament, and Work Order Software

UpKeep is consistently rated the best inventory management software in value for money, ease of use, functionality, and customer support. There’s a reason UpKeep has more 5-star reviews than any other CMMS and Facility Maintenance Software vendor.

Reduce your equipment and asset downtime by up to 26%

Extend your asset and equipment lifetime by up to 11%

Improve overall facility condition with the integration of UpKeep

Achieve up to 652% ROI by integrating UpKeep facility maintenance software into your workflow

Facility Management and Facility Maintenance Software FAQs

It’s unlikely that Aristotle was thinking about facility management when he said “the whole is greater than the sum of its parts,” yet this well-known saying applies. Individual assets, systems, and equipment have a much greater value when they work together to make a facility as a whole operate efficiently, comfortably, and profitably for a business.

Asset operations management (AOM), which focuses on connecting and elevating maintenance, operations, and reliability to a profit center, can play a large role in making facility management more efficient and effective. We’ve answered the questions most commonly asked about facility management and facility maintenance software.

What Is Facility Maintenance Software?

Facility maintenance software is technology that has been designed to help facility managers handle the myriad of details that must be tracked, communicated, and stored to create a long-term, sustainable, and effective facility management program.

At the heart of facility maintenance software is the ability for employees or other users of a facility to submit work requests to a facility management team, alerting them of the need of a repair or request. Ideally, a detailed form along with the ability to capture images can be accessed by smartphone, providing all the necessary information to fulfill the request efficiently.

Once this request is in the system, facility maintenance software can help route the request to the right individual, place it in a priority queue, and provide all the background details, instructions, and historical data at the fingertips of the individual handling the actual work order. After completion, all information is stored within the system so that the management team can run analytics periodically and make smarter business decisions.

For example, if employees notice a machine is suddenly making unusual noises during a shift, they submit a work order describing the problem, along with pictures illustrating the exact location of the noise. The facility manager can schedule a technician immediately or sometime in the next few days, depending on how critical the asset is to the production line. While the technician is inspecting the problem, manufacturers’ guidelines and troubleshooting information can be easily accessed and the technician can see a similar problem was addressed three months ago. If the problem can be resolved, all the work is recorded within the system, including which parts were used out of inventory.

The management team can later review a dashboard that summarizes the performance, maintenance, and failure rates for various assets so that decisions can be made based on data. Perhaps a complete overhaul of the equipment is warranted, or a replacement may be needed down the road.

A similar process can be followed with just about any facility management task, from inspecting safety systems to managing landscaping jobs. Ideally, facility management software helps organize all of those tasks effectively and efficiently.

Next-generation technology often focuses on gathering and organizing a myriad of data that can potentially be generated by built environments. For example, many sensors are available today to monitor things like temperature, humidity, and vibration around the clock. Sophisticated meters, gauges, and other smart devices may be monitoring multiple pieces of critical equipment or systems throughout an organization.

All this data can be used to drive actionable insights or send relevant alerts to a facility management team if the right technology is in place. Sophisticated analytics, machine learning, and artificial intelligence solutions that are integrated into facility maintenance software can help deliver real-time visibility into all aspects of facility management and address potential failures before major damage or a safety incident occurs.

Can Facility Maintenance Software Be Scaled To Fit Small Businesses?

Yes, facility maintenance software comes in various sizes and can be scaled to fit the needs of small businesses to large enterprises.

UpKeep offers various packages to suit businesses of all sizes, such as:

Starter - $45/mo per user

Professional - $75/mo per user

Business Plus - various pricing plans available

For more information, visit our website today.

What Are the Key Features of Facility Maintenance Software?

Common features of facility maintenance software include:

Work order management

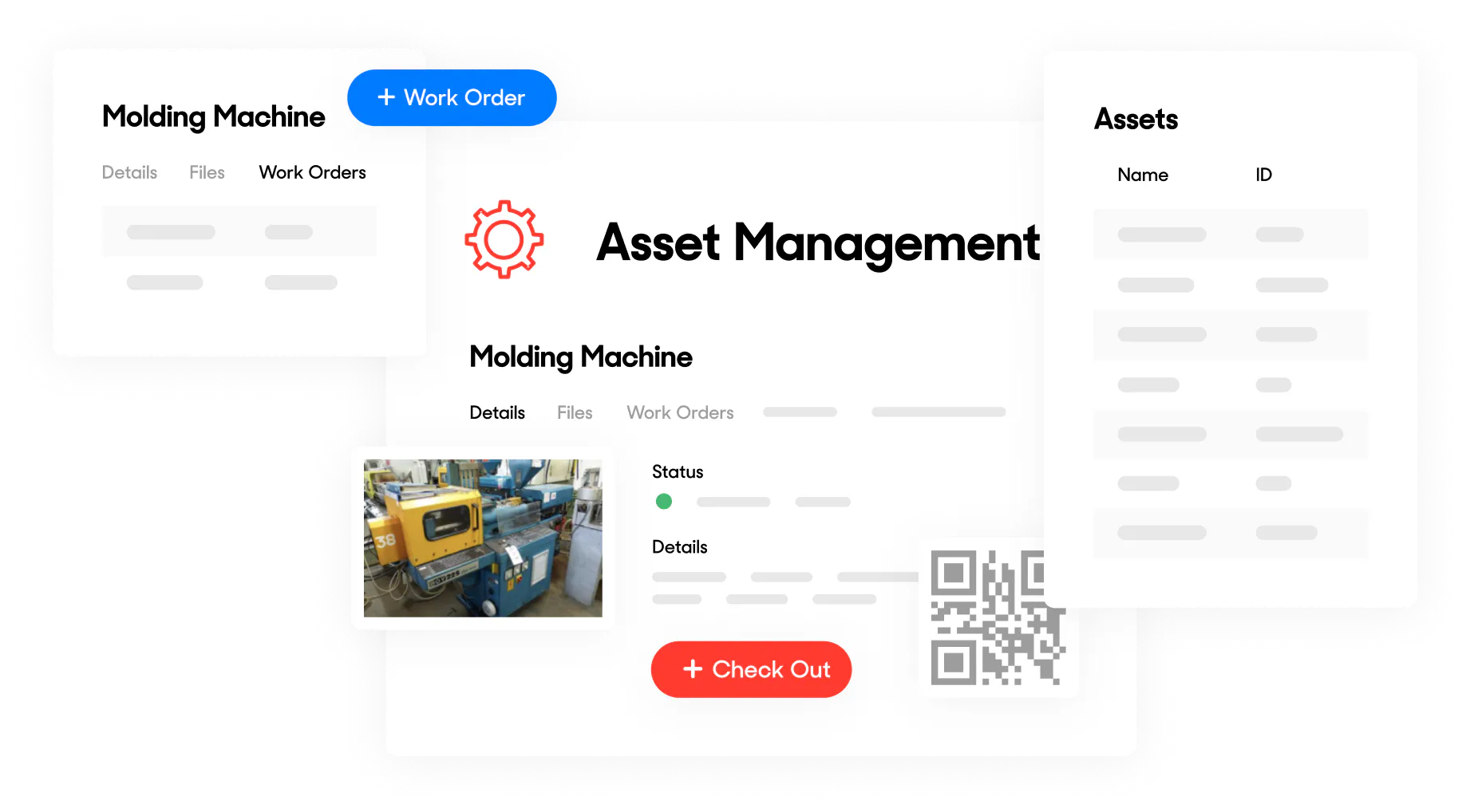

Asset tracking

Preventive maintenance scheduling

Inventory management

Reporting; and

Vendor management

But with UpKeep’s facility maintenance software, you can take facility management further with our reliability dashboard. We provide insights into:

Asset performance

Total downtime

Mean time between failures

Mean time to make repairs

And so much more

Learn how to simplify your workflows, streamline your asset management, and ensure precise documentation by scheduling a tour of UpKeep’s facility maintenance software today.

How Does Asset Operations Management Benefit Facility Management?

Because AOM connects maintenance, operations, and reliability into a system that focuses on critical assets, it can significantly benefit facility management. It captures and leverages active and passive data from each functional area to provide a complete asset operations life cycle view for any organization.

Does UpKeep’s Facility Maintenance Software Offer an Asset Operations Management Solution?

Yes! UpKeep’s AOM solution is mobile-first and designed for ease of use in the field and office, with an emphasis on painless adoption to help create a single source of record.

As a result, facility managers can:

Increase team efficiency and equipment reliability

Optimize asset management; and

Access comprehensive reporting and analytics

Facility management is something most employees and other users of buildings or facilities take for granted. As most people go about their days, they don’t notice how important it is for their surroundings to be comfortable and supportive of their tasks at hand.

AOM can play an important role in helping facility managers ensure their buildings, plants, or production lines are optimized, safe, and efficient by bringing together the best of maintenance, reliability, and operations.

Trending Resources

Book

We Wrote the Book on Asset Operations!

UpKeep brought maintenance, reliability, and operations teams together in a new approach called Asset Operations Management. Now, we’ve written the book! We’re thrilled to announce the publication of Asset Operations: The Future of Maintenance, Reliability, and Operations.

Blog

4 Ways to Reduce Facility Costs With Lean Maintenance

Blog

What is Facility Management?

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability