What are common use cases for using a temperature sensor in predictive maintenance?

Various industries, including automotive, petrochemical, and aerospace, use temperature sensors as part of predictive maintenance. Most pieces of equipment don’t fare too well when temperatures get too high or too low, so using infrared (IR) imaging, thermocouples, or even a simple thermometer can be useful for detecting issues.

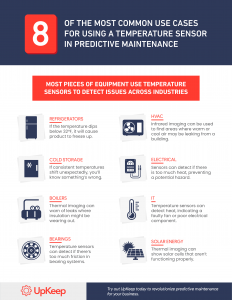

Use Cases

Some common use cases might include the following.

Refrigerators

If the temperature dips below 32°F, it will cause product to freeze up. Below-freezing temperatures in a commercial refrigerator may indicate a problem within the system.

Cold storage

Many products need to be kept at very consistent temperatures. If those temperatures shift unexpectedly, you’ll know something’s wrong.

A simple example is a freezer. A freezer’s whole function relies on maintaining a consistent temperature, so the sensor would be used to tell if the internal temperature deviates from normal.

Boilers

Thermal imaging can warn of leaks where insulation might be wearing out.

Bearings

High friction causes heat, meaning temperature sensors can detect if there’s too much friction in bearing systems.

HVAC

Infrared imaging can be used to find areas where warm or cool air may be leaking from a building.

Electrical

Poor electrical connections generate heat. Too much heat means there’s a potential hazard.

IT

IT components such as servers and computers can be damaged if they overheat. High readings on a temperature sensor might indicate a faulty fan or poor electrical component.

Solar energy

Solar cells that aren’t functioning properly will often stand out on thermal imaging.

Conclusion

On the other hand, temperature isn’t core to the function of a bearing system, but if things get too hot, it can indicate something else is going wrong. In this case, the sensor is used to pick up a sign (increased temperature) that the system is unbalanced or poorly lubricated.

In any of these cases, you can use the sensor in predictive maintenance by setting specific temperature ranges in your CMMS program. If the sensor reports temperatures too high or too low, you’ll get a notification letting you know that maintenance needs to be done.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)