When should I start a predictive maintenance program?

You should start a predictive maintenance (PdM) program if you already have a preventive maintenance program in place and want to further improve uptime, overall equipment efficiency, and other maintenance metrics. I don't recommend moving from a reactive maintenance program to a predictive maintenance program. In most cases, this is too aggressive of a jump.

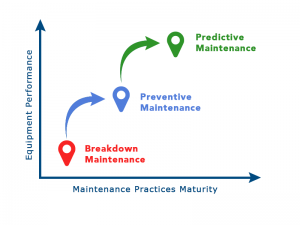

Crawl, walk, run

If you look at the evolution of maintenance strategies as a journey of three phases...

- Reactive maintenance

- Preventive maintenance

- Predictive maintenance

...you want to follow the natural order of progression. There are some exceptions, but this is usually the case. Organizations that try to evolve their maintenance strategy too fast will end up wasting time and money. Adopting a PM program first will get your team comfortable with using PM software and operating on a proactive basis rather than a reactive basis.

How do I start a PdM program?

For those of you who already have a preventive maintenance program in place, the best way to start a PdM program is to choose one piece of equipment.

Buy the necessary PdM tools for that equipment, train technicians how to use the tools, and put workflows in place that alert you when equipment reaches a "yellow zone" condition.

If you can do this successfully for one asset, you can probably do it successfully for another asset. And if you can do it successfully for two assets, you can probably do it successfully for four assets. And on and on...

Keep growing on the foundation you build and always stay aware of metrics that indicate whether PdM is a worthwhile program:

- Are less work orders being created for assets?

- Is uptime higher for assets?

- Do saved parts and labor costs outweigh the cost of PdM tools and training?

Answering these questions will help you determine if PdM is worth pursuing further.

Want to keep reading?

Return on Investment (Predictice Maintenance)

The 6 Sensors for Predictive Maintenance That Optimize Repair Timelines

Predictive Maintenance Machine Learning: The Maintenance Leader’s Guide

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)