What are the best ways to layout my warehouse?

The best way to organize your warehouse will depend on your business, inventory, growth projectile, time and budget limitations, and many other factors. Because warehouse layout can significantly affect so many factors of your business including safety, efficiency, and ongoing labor costs, it’s important to invest time and effort in research and planning before creating a design and purchasing racks and equipment.

Draw on Experience

If you’re starting from scratch, begin by studying best practices in your particular industry. Look at comparable companies in terms of business and size, and learn as much as you can from their experience. Be sure to incorporate automation, unique item tagging or barcoding, and a centralized computer system from the beginning.

If you’re re-working or expanding an existing warehouse, tap into data from your CMMS, supply chain management software, or inventory software to identify improvement opportunities.

Design to Current Needs with Ability to Expand

As a result, it’s important to design a warehouse layout to meet your current needs. However, you’ll also want to leave room to grow and expand easily in the future.

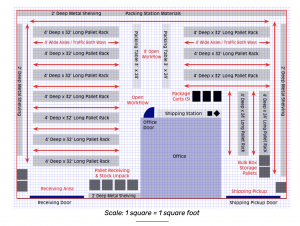

Use a Schematic and Test Your Design

Because warehouse layout can affect so many aspects of your business, it’s imperative to map out the details using a blueprint of your warehouse onto a paper schematic. Consider things like physical limitations of your space; placement of columns, windows or offices; even things like the direction that doors open and close.

Before you actually install your racking and other equipment, create a mock design using masking tape. Have your employees and drivers move around your planned warehouse, simulating various daily scenarios. Make notes of their suggestions and incorporate changes before permanent fixtures are installed.

What are the best ways to organize your warehouse?

The best ways to organize your warehouse involve wise layout design, management software, and labeling systems. Well-organized, tidy warehouses make the entire process of receiving items, moving them to the proper locations, and shipping them to customers easy and efficient. Here are some tips and ideas to consider.

Physical Layout Design

Optimizing the physical layout design of your warehouse can increase efficiency and improve overall organization.

Consider systems such as stackable bins and shipping stations that can make the physical space in your warehouse more efficient. Keep the warehouse clean, store like items together, and minimize the actions required to conduct daily tasks throughout the warehouse.

What is warehouse racking?

Warehouse racking is the system of shelves, configuration, and location of the physical structure required to hold your inventory items. Typically made from plastic, metal, or wood, warehouse racking plays an important part in how easy it is to store and retrieve your inventory items as well as how efficiently your warehouse operates.

Types of Racking

The most popular kind of warehouse racking is called selective racking. In this system, aisles can be narrow as they only need to provide enough space for one pallet to move through. Employees or robotic picking systems select items from the aisle and they are only one pallet deep.

In warehouses that require dense storage, you may choose a drive-in or drive-through racking system. The system you select depends on your inventory process. If you use a last-in-first-out (LIFO) process for low turnover items, you’ll want a drive-in racking system. If you stock items that have a use-by date and follow a first-in-first-out (FIFO) process, you’ll want a drive-through racking system.

Another racking system for LIFO processes and high-density storage is the push-back rack. These racks are typically as deep as two to five pallets and moves the rows forward or back on rails and carts depending on inventory volume. Similar to push-back racks, gravity racks perform in a vertical plane, receiving new goods at the top and dispensing older goods from the bottom.

In addition, this system must play one role in overall inventory management. Labeling, barcoding or RFID technology as well as a centralized computer system like a CMMS must work hand-in-hand with a racking system so that inventory can be easily accessed and managed efficiently.

Software Solutions

A wide range of technology solutions are available today to help companies better manage warehouses. According to the Logistics Bureau, about 85 percent of distribution centers had implemented some sort of warehouse software by 2015.

Systems such as CMMS with an integrated inventory management system can go a long way in helping to collect, store, and organize data about the quantity and location of inventory items. Understanding what items are in stock, where they are located, and when reorders are needed is critical to managing an organized warehouse.

Software systems can also help sequence the order of selecting items by most efficient path or grouping items together to help companies better organize their workflow.

Labeling Systems

Barcoding technology as well as RFID tags have advanced in capabilities and dropped in price in recent years, making it easier than ever to label assets and inventory items. By tagging items upon arrival and scanning codes into a centralized computer system, warehouse management can easily track how those items are moving through the warehouse, into production or usage, or through to a final product or disposal.

Want to keep reading?

What are the best ways to organize your warehouse?

Inventory Management

How to Transition from Paper Work Orders to a CMMS

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)