What are common preventative maintenance schedules and checklists for a boiler?

Boilers are heavy-duty equipment that generate hot water or steam by burning fuel. Boilers generally operate under high temperatures and pressures. Given that they are subject to extreme working conditions, it is important to ensure that they are properly maintained - not only for reliability purposes but for safety as well.

The U.S. Department of Energy provides a practical checklist to serve as a guide to maintaining boilers. To make the most of the given checklist, it would help to first familiarize yourself with the general types of boilers, and their key components.

What are the different types of boilers?

Boilers are generally one of three main types – fire-tube boilers, water-tube boilers, and electric boilers.

Fire-tube boilers

Fire-tube boilers operate by letting hot combustion gases flow through tubes submerged in water. This converts the water surrounding the tubes to hot water or steam. Fire-tube boilers operate at relatively low pressures of around 150 psi (~10 bar).

Water-tube boilers

With water-tube boilers, water passes through tubes surrounded by hot combustion gases. Its design allows for significantly higher pressures of up to 3500 psi (~240 bar). With higher operating pressures, this type of boiler has a broader range of applications – from small residential uses to larger industrial utility classes.

Electric boilers

As the name suggests, electric boilers generate hot water or steam from electrical ratings. They are typically used in heating, ventilation, and air conditioning (HVAC) applications.

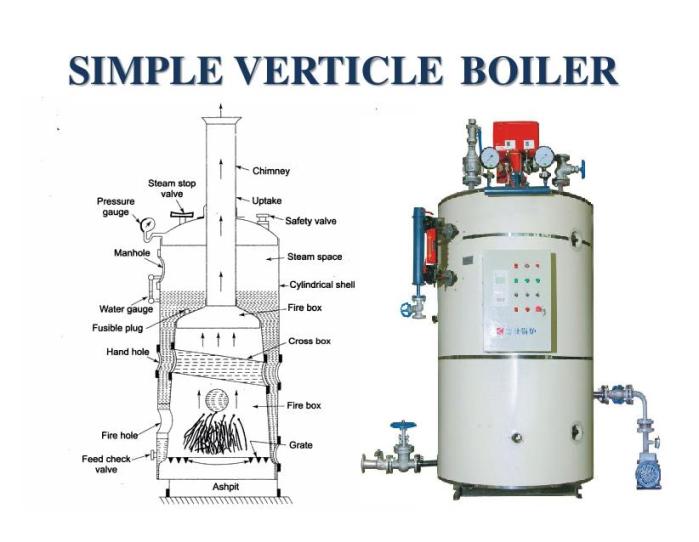

What are the critical components of a boiler?

The critical components of a boiler directly impact its reliability and safety. These components include:

Drum

The single, most expensive part of the boiler. Problems with the drum are usually related to corrosion or excessive localized stress.

Headers

Next, headers act as outlets for superheated fluids. They can be susceptible to deformation from exposure to fluctuating high and low temperatures and thermal stresses.

Tubing

These components are the most common causes of failure due to varying ranges of wear and tear. While tubing usually lasts for long cycles, localized stresses and corrosion can significantly accelerate its deterioration.

Piping

As with headers and tubing, piping systems can be subjected to excessive stresses from long-term operation under extreme heat and pressure conditions.

Deaerators

Lastly, these components must meet industrial standards for oxygen levels within the boiler. Without proper maintenance, they are prone to corrosion and deterioration.

Is it safe to use boilers?

The short answer is yes – with proper operation and maintenance, boilers are now safe to use and have become an integral part to some facilities. It is useful to know, however, that this wasn’t always the case.

Since the early 1900s, government and professional organizations put resources into prioritizing the importance of boiler safety. They introduced codes, standards, and checklists to ensure that boiler safety is second-nature. These best practices have realized not only the reliability of equipment but also the safety of the people that use them.

Preventive Maintenance Checklist for Boilers

Finally, the following checklist provided by the US Department of Energy is one of those valuable guides in making sure that proper routine checks are being made for boiler safety and efficiency.

Want to keep reading?

Boiler Preventive Maintenance Program & Checklist

Should you perform HVAC preventive maintenance?

What are common preventative maintenance schedules and checklists for a steam trap?

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)