Asset Performance Management (APM)

What is an Asset Performance Management (APM) system?

Asset performance management (APM) systems are an array of tools that strive to both improve equipment availability and reliability, while limiting risk and cost. In theory, this is what every APM solution offers industries, such as most industrial organizations and maintenance companies. In practice, it depends on what system you choose and what you need to use it for in the long run.

Let’s take a look at how APM systems work in general terms and what makes a good APM system great for industrial maintenance, preventative maintenance, and the maintenance industry in general.

How Asset Performance Management Systems Work

Data has always been a huge part of improving equipment. APM systems chiefly work by analyzing this data through a complicated set of filters. The end result tells the user where improvements should be made and what’s available at any given point in time.

This varies across the different asset performance management systems that are available today. An APM that is designed for the industrial maintenance industry will have different data filters than a preventive maintenance APM system. In comparison, a city’s APM system will look dramatically different than one in other industries.

What’s the Difference Between an APM and a CMMS?

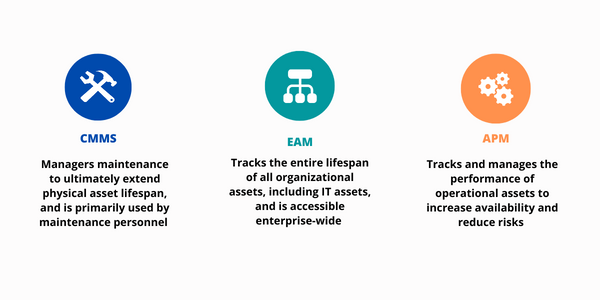

A CMMS (Computerized Maintenance Management System) may seem to be almost the same thing as an APM system. They are both software systems that store information and data about maintenance.

However, the main difference between the two is that CMMS software and platforms actively extend the lifespan of physical assets in your company. APM systems track, manage, and analyze the performance of your operational assets to decrease risk and increase productivity.

The benefits of asset performance management (APM) systems

Targeted maintenance tasks

An APM system gives you the information you need to target preventive maintenance tasks at key areas in your processes. That way, there is less time wasted on PMs that accomplish nothing, and equipment is neither over-maintained nor neglected.

Improved equipment efficiency

As you target PMs where they’re needed most based on data, equipment efficiency improves. Less energy is used, less material is wasted on production rejects, and more time is spent producing quality results.

Targeted improvement

As you take a full systemic approach to APM, you’ll not only be able to track the needs of individual pieces of equipment, but also those of your processes as a whole. The data you collect can be analyzed to see where bottlenecks and other inefficiencies occur, allowing you to target specific areas for improvement, whether those involve the equipment itself or your maintenance workflows.

Safer work environment

As you monitor equipment performance, you’ll be able to detect machines and other assets that are operating outside of safe parameters. This alerts you to problems that may develop in the future, allowing you to resolve them before an accident happens.

Improved reliability

The end result of all these benefits is to improve your facility’s reliability. Equipment works better, there are fewer breakdowns and safety hazards, and you’re able to enjoy increased productivity.

What components make up a successful asset performance management system (APM)?

Modern APM systems incorporate advanced technologies and intelligent design. As such, the following components will help make your asset performance management system successful.

Advanced predictive capabilities

Predictive maintenance provides higher cost savings than preventive or reactive maintenance strategies, topping out at roughly 12% more cost savings than PM.

Advanced PdM capabilities allow maintenance teams to not only track data, but also to analyze it through modeling and machine learning software. These types of software gather data from sensors and reports, discover trends, and then model those trends in visual format.

As the data departs from how the equipment should work, the system can alert you to a need for maintenance work, even going so far as to prescribe the most cost-effective solution to the problem. This capability allows for a strictly as-needed maintenance approach, based on preventing failures long before they occur.

Complete system-level analysis

Data should not only come from sensors on individual assets, but also from other sources such as work order histories, MRO inventory counts, and so forth. Individual assets in a production line should not only be monitored on an individual basis, but also on a holistic level as well.

The truth is few equipment failures—and the disruptions they cause—occur in isolation. By taking a system-level approach to your asset performance management, you’ll be able to assess data from multiple areas, giving you a clearer, more complete picture of how faults occur in your facility.

Safety and compliance

Reducing equipment downtime isn’t the only priority. The system you use should also account for safety and compliance. If your equipment starts operating outside of acceptable parameters, you’ll need to be made aware of that fact.

By using an APM system that not only incorporates the possibility of equipment failure but also relevant regulations and safety requirements, you can reduce the number of accidents in your facility, at once lowering liability and improving the quality of your work environment.

Prioritization

Not every problem is important to handle right away, and in some cases, taking preventative measures with your equipment may not even be necessary. Some pieces of equipment are most efficiently maintained on a run-to-failure model, whereas certain types of failures may not be impactful enough to prevent at all.

Your asset performance management system should be designed to give you a clear view the cost of failure versus the cost of prevention. By comparing costs, including in terms of environmental, health, and safety as well as those of lost uptime, you’ll be more able to prioritize the right tasks and perform better-targeted PMs.

Real-time alerts

Your asset performance management system should be consistently up to date on what’s going on in your facility. However, that will mean nothing if it doesn’t provide real-time alerts when something needs attention. As your system analyzes what’s happening with your assets, it should also generate alerts when the data passes key thresholds.

Using real-time alerts not only makes sure important maintenance tasks are performed promptly, but also to save time, since it eliminates the necessity for managers to be constantly watching your data portal themselves.

7 tips for asset performance management (APM) implementation

To be truly effective, APM needs to be implemented properly. Poor APM can result in a loss of up to 1.5% of all sales revenue, so optimizing your asset performance management is important. The following tips can help you accomplish that.

1. Create a data-driven maintenance culture

When implementing an APM system, it’s important to know that your asset performance management practices should extend beyond the software itself. It’s a strategy that should seep into your maintenance team’s entire culture.

APM works best in maintenance environments that already take a preventive approach to their processes. As such, if your maintenance team tends to do more firefighting than regular upkeep, you may need to work on establishing forward-thinking practices before the data-driven capabilities of modern APM will yield their fullest benefits to you.

2. Align your APM strategies with business goals

The effectiveness of your APM will depend a great deal on how much support you can get for it from the upper leadership in your company. As such, it needs to support overall business objectives. Demonstrating that it does so will be key to getting the resources you’ll need to handle the upfront costs of modern APM.

For example, if one of your business goals is to make sure your customers are always pleased with the quality of your products, you might want to demonstrate how a modern APM system can improve product quality by eliminating rejects. As you’re better able to monitor the performance of your equipment, the odds of abnormalities in the production process diminish, thus reducing waste and creating consistently high-quality output.

3. Get familiar with the technology

An APM system is centered in advanced technology, so you’ll want to get as familiar with that technology as you possibly can. It takes time, but it’s crucial to use the system effectively.

For many facilities, and particularly those that aren’t currently monitoring their equipment, a step-by-step approach may be best. Begin by monitoring one or two key assets, then expand to a full production line, and then work on incorporating other systems. Over time, your team will get a stronger grasp on both the principle of monitoring equipment performance as well as how to best use the technology involved.

4. Get needed skills on board

In connection with knowing the technology and using it properly, you’ll need the right types of skillsets on board. The maintenance world is becoming more and more tech-centered, which means your technicians will need strong technology and diagnostic skills rather than manual labor capabilities.

Some of the key skills you should have in your maintenance team include:

- Analytical skills

- Attention to detail

- Technology skills

- Communication ( you need to get operations on board, so communication is key)

- Problem solving

In addition, handling the infrastructure needed to support an APM system will require a properly skilled information technology department.

5. Connect asset performance management system (APM) with other business systems

Asset performance management shouldn’t operate in isolation. To be most effective (and to align with overall business goals), it should be used in connection with other systems, such as enterprise resource management (ERM), your CMMS, business intelligence software, and so forth. Safety, finances, and other matters also need to be taken into consideration when developing your APM strategy.

The reason for this is because you need a holistic view of your production processes. Without that, APM suffers. With that data coming from other systems and departments, it allows you to make well informed decisions regarding the upkeep of your equipment.

6. Pay special attention to key data points

While data in general is a good thing, there are a number of items you particularly won’t want to neglect. Some of this data is directly related to the condition of your equipment, such as:

- The flow of energy through your system, which can reveal inefficiencies, bottlenecks, and so forth.

- Temperature, specifically in key points of the equipment where excess heat can indicate a problem.

- Noise and vibration, which may indicate wear and tear on assets.

In addition, make sure you note the difference between leading and lagging indicators. Leading indicators are points of data that show something is likely to happen in the future, whereas lagging indicators show that an event has already occurred.

7. Use the data you gather

Your APM system helps you gather and structure data in a way that can help you improve reliability and reduce costs in your facility. However, for it to actually accomplish that, you’ll need to make use of it. According to Harvard Business Review, only about half of all structured data is ever used in business decisions. The rest is often wasted.

Incorporating APM into your overall maintenance management processes can help you avoid that waste and make the most of your data. In short, look at your data and use it often.

Conclusion

An APM system is a software solution that provides valuable insight into your equipment. When used as part of an overall asset performance management strategy within your maintenance processes, it can help you maintain equipment on a level that isn’t as easy to manage otherwise.

Want to keep reading?

Asset Management

How Can I Manage Asset Life Cycle to Reduce Total Cost of Ownership?

The Advantages & Disadvantages of Preventive Maintenance

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)

In the data-driven world that we live in today, asset performance management systems rise to the challenge. By using the data companies automatically generate each day, an APM system can close off reduce ineffective company processes. Additionally, an APM can identify where improvements need to be made in the future. Overall, an APM can increase asset availability, reduce operations and maintenance costs, and more.

In brief, these systems can take a good company and make them a great company.