Blog Post

The Hidden Side of Robotics and Automation In Manufacturing: Unveiling the Price of Maintenance

Over the past several weeks, I’ve been discussing potential solutions to the ongoing labor shortage in manufacturing. For a long time, I’ve believed that things like immigration and other methods of recruiting low-skilled labor are only short-term fixes; that we really need to turn to innovation, automation, and robotics as the long-term solution to overcoming our labor problems. But this week, in speaking with one of UpKeep’s customers, I’ve realized that I missed a big factor in holding that opinion: the cost to maintain, support, and repair complex, highly technical systems after installation. The cost is significant and is often lost in the guise of operating in perfect conditions and humanless ROI. But, before you deploy robotics and automation, consider the ongoing maintenance costs.

Want to keep reading?

Article

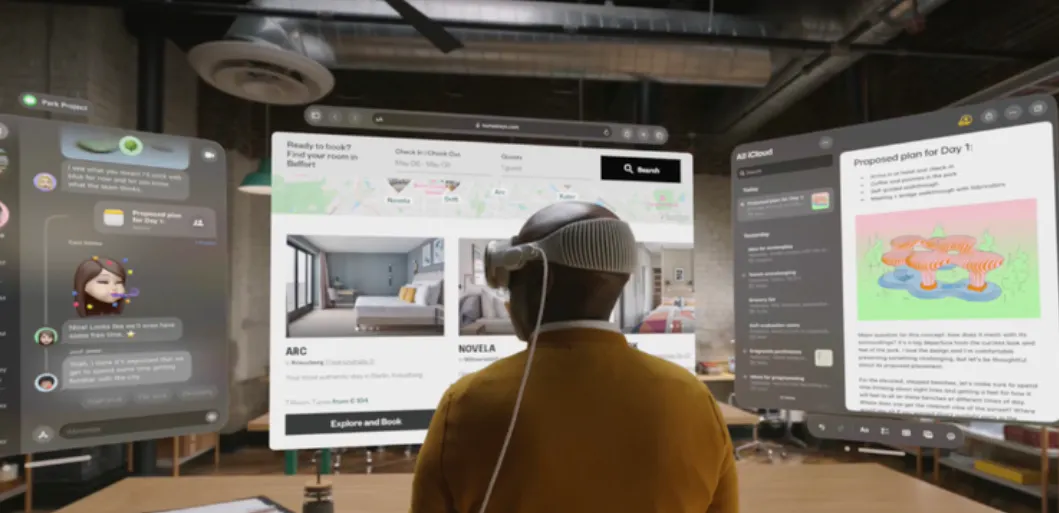

Will the Apple Vision Pro Finally Solve The Labor Shortage In Manufacturing? I Doubt It. Here's Why.

Article

Balance Cost-Cutting with Smart Investments in Manufacturing and Maintenance During Recession

Article

It’s Time to Face Reality: We Can’t Fill 2.1M Manufacturing Jobs. Automation is the Only Way Out.

4,000+ COMPANIES RELY ON ASSET OPERATIONS MANAGEMENT

Leading the Way to a Better Future for Maintenance and Reliability

Your asset and equipment data doesn't belong in a silo. UpKeep makes it simple to see where everything stands, all in one place. That means less guesswork and more time to focus on what matters.

![[Review Badge] Gartner Peer Insights (Dark)](https://www.datocms-assets.com/38028/1673900494-gartner-logo-dark.png?auto=compress&fm=webp&w=336)